BL09U INFORMATION

Experimental Techniques

- HAXPES (Hard X-ray Photoelectron Spectroscopy)

Overview

This beamline utilizes monochromatic X-rays obtained by a double-crystal monochromator with an undulator as the

light source. It covers the tender to hard X-ray energy range; however, the energy is fixed at 6 keV for HAXPES

measurements.

Beam Characteristics

- Energy

- (2.1)5~15 keV

- Flux

-

3.7x1012~7x1013 cps

(Calculated value, depends on energy and experimental conditions)

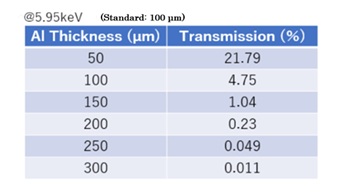

* Al filters for adjusting light intensity are installed inside experimental hutch 3.

(Users can freely combine and select from 50 μm, 100 μm, and 150 μm thicknesses.)

- Beam size

-

• Value obtained by measurement with a Au 30 µmΦ wire.

TOA=0° < 12.5 µm(H) x 3 µm(V)

TOA=88° < 360 µm(H) x 3 µm(V)

Hutch size

Approx. 9.5 m (along the beam axis) x 4.5 m (width) x 4 m (height)

Light Source and Optics

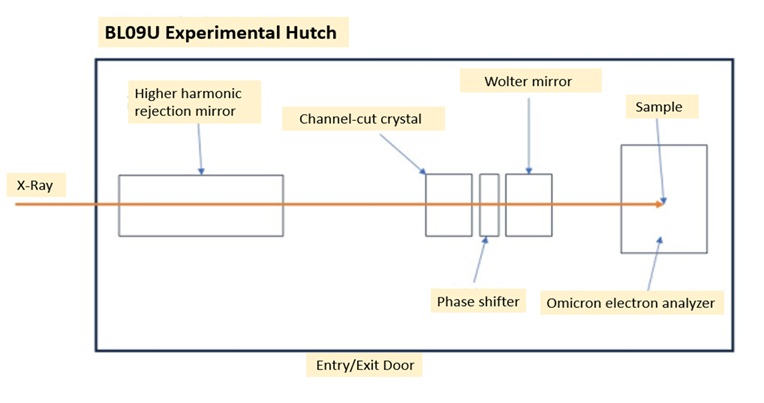

This beamline utilizes a 166-pole, 22 mm period in-vacuum undulator as its light source, and a monochromatic X-ray beam is available after passing through a liquid nitrogen-cooled Si(111) double-crystal monochromator. A double- mirror system for harmonic rejection is installed in the experimental hutch. Downstream, a channel-cut crystal and a Wolter mirror are installed.

Experimental Station

-

Experimental Equipment

- [Hard X-ray Photoemission Spectroscopy (HAXPES) system]

- Detector

- [Scienta Omicron electron analyzer]

- About Samples

-

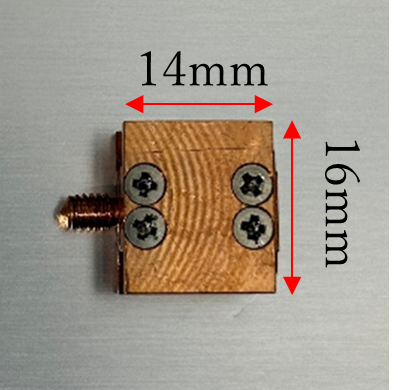

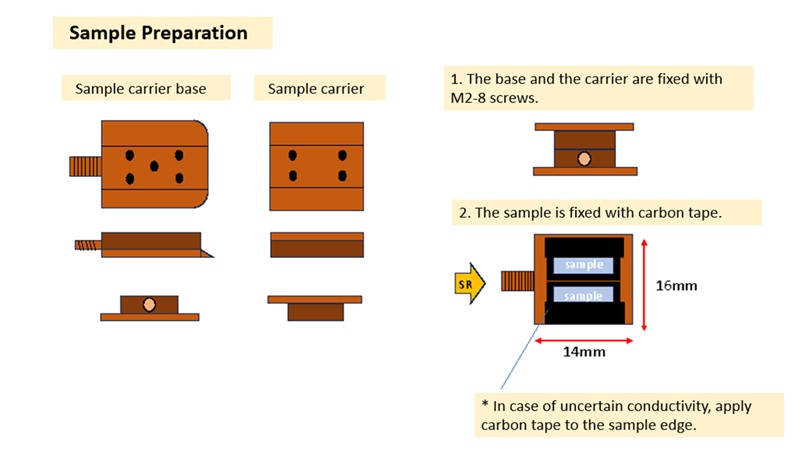

Sample size: Max. 16 mm (height) x 14 mm (width) (thickness: 2.5 mm or less)

*If the sample thickness is 2.5 mm or more, a different sample transfer method will be required. Please consult with your assigned concierge or the beamline staff before submitting your reservation request.

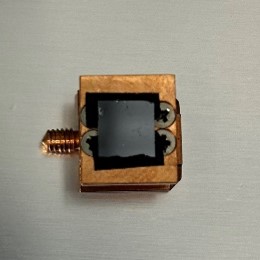

Sample carrier size Example of sample mounting (Si substrate)

: 16 mm (height) x 14 mm (width) : 7 mm (height) x 7 mm (width) x 0.65 mm (thickness)

Samples are fixed using carbon tape.

Note: Measurements may not be successful for non-conductive samples.

Please consider applying a conductive coating (e.g., metal deposition) to the sample surface to ensure conductivity.

Note: By cutting the sample size to approximately 4 mm (height) x 10 mm (width), it is possible to mount three samples on one sample carrier.

Note: The manipulator in the main chamber can hold five sample carriers.

Regarding Charge-up Mitigation

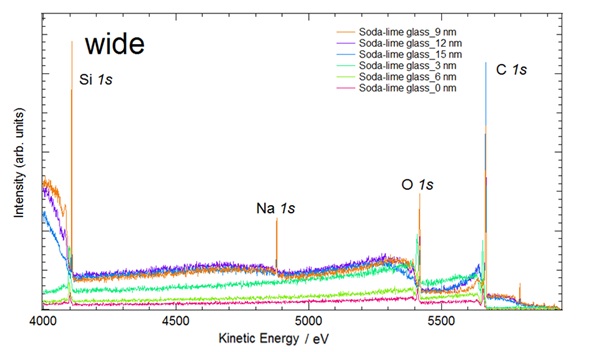

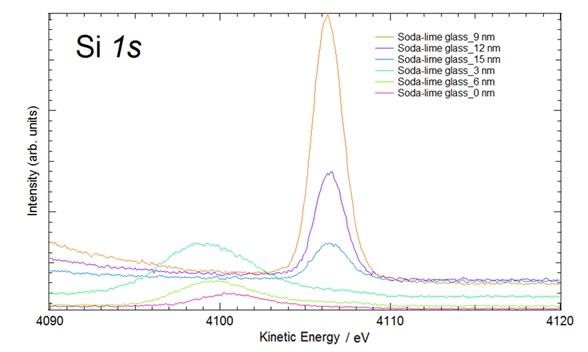

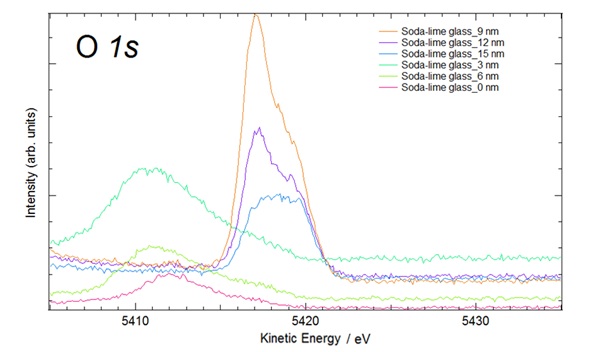

The sufficient coating thickness for charge-up mitigation using carbon coating was investigated.

Samples were prepard by coating slide glass(Na2O-CaO-SiO2) using the SANYU QUICK CARBON COATER SC-701CT with 6 different thickness: 0, 3, 6, 9, 12 and 15 nm.

Charge-up was observed at 0, 3, and 6 nm, and Na (substrate information) was not detected.

At 9 nm and above, the spectrum stabilized, and Na (substrate information) was detected.

Furthermore, since the sensitivity of substrate information was better at 9 nm compared to 12 and 15 nm, a carbon coating thickness of around 10 nm is recommended.

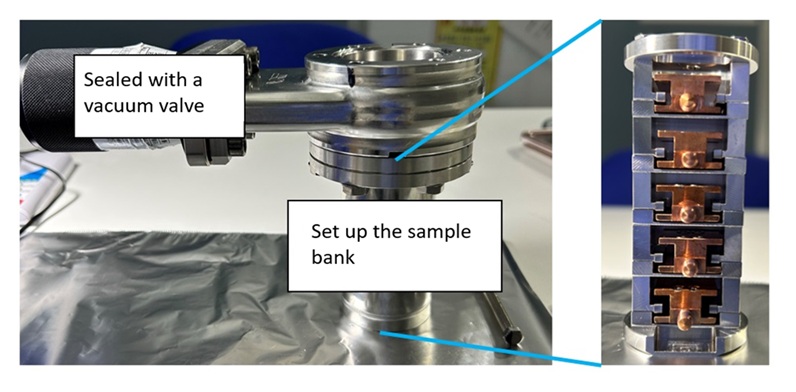

Regarding sample prepared under inert atmosphere:

Sample transfer without exposure to the atmosphere is possible using a transfer vessel.

Up to five sample carriers prepared as described above can be loaded simultaneously.

(Sample thickness: 2.5 mm or less)

Note: If other user experiments requiring the transfer vessel are scheduled before or after your allocated beamtime, the transfer vessel may be used for samples that can be exposed to the atmosphere in order to minimize time loss between experiments.

- Regarding sample carriers:

-

Due to the limited number of sample carriers, we do not offer pre-rental.

If you require sample carriers for pre-sample preparation, it will be necessary for each user to have them manufactured.

We do not have any specific recommendations for a manufacturer, but our foundation has previously ordered the same type of sample carriers from Vacuum Optics Co., Ltd.

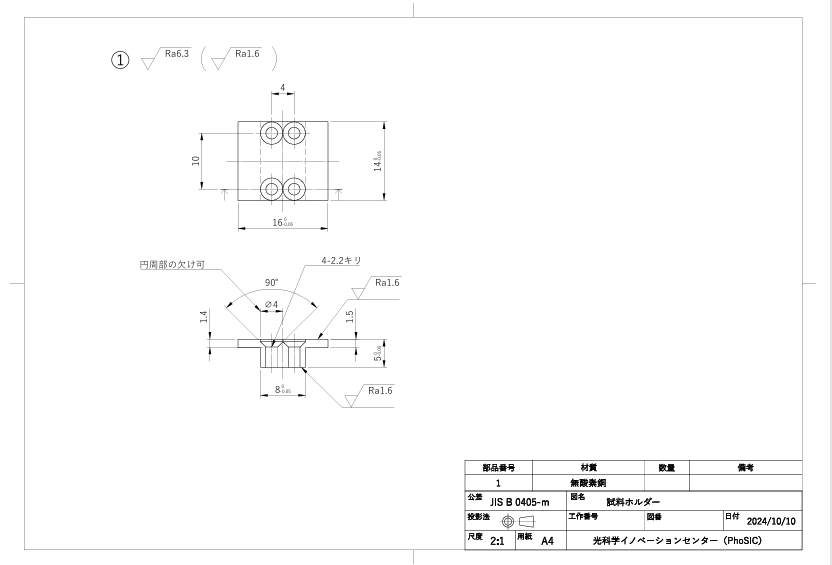

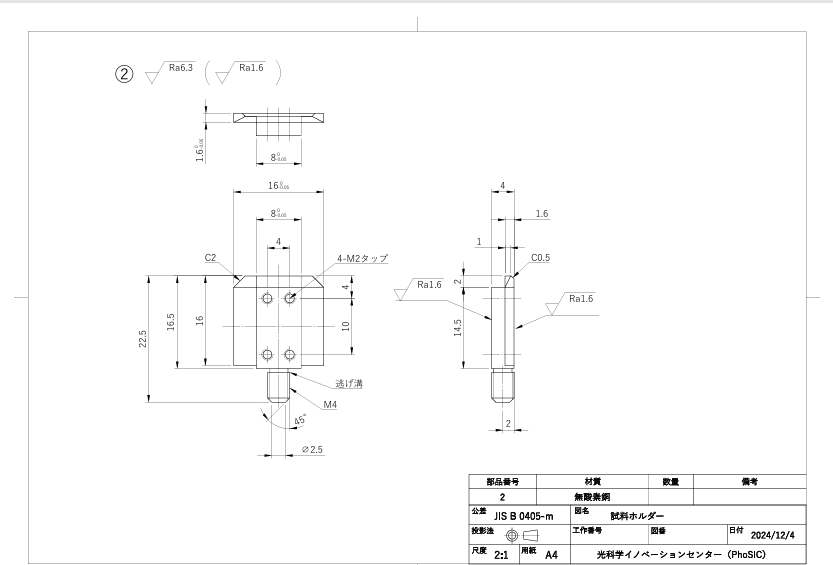

*The sample carrier drawing is as follows:

(Click to display as a PDF)

Sample carrier (plate)**

Sample carrier (base)**

Note: M2-8 countersunk screws are required to fix the above carrier (4 screws per carrier).