BL08W XRD INFORMATION

Experimental Techniques(All are standard measurements)

- X-ray Powder diffraction

- 2D X-ray diffraction mapping (Prior consultation with PhoSIC is required)

- Surface X-ray diffraction (Prior consultation with PhoSIC is required)

- In-situ X-ray diffraction (Prior consultation with PhoSIC is required)

- Element mapping using X-ray fluorescence

Overview

This is a hutch equipped with a general-purpose X-ray diffractometer. Powder diffraction measurements of samples

enclosed in capillaries are possible using a capillary spinner for powder diffraction and a two-dimensional (2D) detector

(standard measurement). Mail-in measurements are also accepted.

Furthermore, it is possible to perform diffraction mapping and in-situ experiments. Diffraction mapping involves

placing a sample on the general-purpose sample stage and moving it horizontally and vertically to record diffraction

patterns at each point. In-situ experiments involve measuring diffraction patterns while changing the sample's

environment. Users must bring their own equipment for controlling the sample environment. Usable gases are limited

to harmless gases, such as N2 and CO2. Surface X-ray diffraction is performed by placing a sample on the powder

diffraction spinner and controlling the angle for measurement. For these specialized measurements, please consult

with the PhoSIC staff before booking beam time.

2D elemental mapping using X-ray fluorescence is performed by placing a sample on the general-purpose sample stage

and moving it horizontally and vertically to detect X-rays at each point.

Light Source and Optics

The branchline for XRD measurement provides monochromatized X-rays. A white X-ray beam generated by a 5-pole multipole wiggler light source is monochromatized using Bragg reflection from a Si crystal and is split off-axis from the original beam. The X-ray energy can be selected by choosing either the Si(111) or Si(220). Focusing is performed by a bent cylindrical mirror.

Beam Characteristics

- Energy

-

17.5 keV or 28.5 keV

The default energy is 17.5 keV, and we can accommodate 28.5 keV upon request. Please specify the desired energy when making your beamtime reservation.

We do not switch the energy during beamtime, as it may affect other branches. - Flux

-

Example of an actual measurement value at a storage ring current of 200 mA

17.5 keV 1.2 x 1011 cps

28.5 keV 7.0 x 109 cps- Beam size

- Example of an actual measurement value at the powder diffractometer sample position:

120 µm(horizontal)、70 µm(vertical)- Hutch size

- Approx. 3m (optical axis direction) x approx. 2m (width) x approx. 3.3m (height)

Experimental Station

- Experimental Equipment

-

[Spinner for powder samples]

• Sample-to-detector distance : approx. 240 to 890 mm

• Measurement range : 2 Θ < 50 degrees:(For 17.5 keV, it is equivalent to CuKa at 133 degrees)

• Powder and liquid samples can be sealed in a capillary

【Example of how to prepare a capillary sample】

• The sample holder is equivalent to those of SPring-8 BL19B2 and AichiSR BL5S1.

• CeO2 and Si are available as standard samples.

• The rotation axis can use a camera-based automatic alignment mechanism.

• Several software packages for converting data to 1D are available. However, analysis software, including for the "Rietveld method", is not installed. Please ask a staff member regarding the application of the Rietveld method.- [Large Area IGZO Flat Panel Detector]

Hamamatsu Photonics K.K. C14406DK-2918

• Detection area: 430 x 430 mm

• Pixel size: 140 µm2

• Scintillator: Directly deposited CsI

• Frame rate: Maximum 15 fps (full frame)

• Dynamic range: 87 dB- [General Purpose X-Z Stage]

Kohzu Precision Co., Ltd. XA07A-L202 and ZA07A-V1F01

• Sample-detector distance: Approx. 100 ~ 580 mm (Adjustable by lab jack)

• Three types of user cables (one BNC, one LAN, and three USBs) are available for use inside and outside the experimental hutch. If you wish to use them, please inform us when making your reservation.

Please note that in the case of USB cable connections, it is possible that the equipment may not operate properly depending on your device. Please consider necessary countermeasures in advance.

• Other types of automated stages are also available. Please consult with us if you wish to use them.- [Fluorescent X-ray analysis and elemental mapping by fluorescent X-ray]

TechnoAP Co., Ltd. Single-element silicon drift detector XSDD30-01GRCL-ICF

• The sample is set on the X-Z stage tilted at a horizontal 45-degree angle to the X-rays, and fluorescent X-ray are detected in the 90-degree direction.

• Effective area: 28 mm2

• Window: Graphene

• Maximum count rate: 1 Mcps

• Cooling: Peltier element

Because measurements are taken in the atmosphere, absorption of fluorescent X-rays by the air occurs. Therefore, elements heavier than sulfur (mainly transition metals) are the subjects of measurement. For elemental mapping, the sample is moved on the X-Z stage to scan the sample with X-rays. After measuring at each position, the fluorescent X-ray spectrum (MCA data) is read. The time required for data reading and moving the sample stage is 0.2 to 0.3 seconds. The data accumulation time at each position depends on the concentration of the target element.

Software for visualizing element distribution is available.

As described above, since the size of the X-ray beam is approximately 100 µm, the maximum spatial resolution is also about the same.- [Others]

For sample alignment, a web camera and a laser coaxial with the X-ray are available. - [Large Area IGZO Flat Panel Detector]

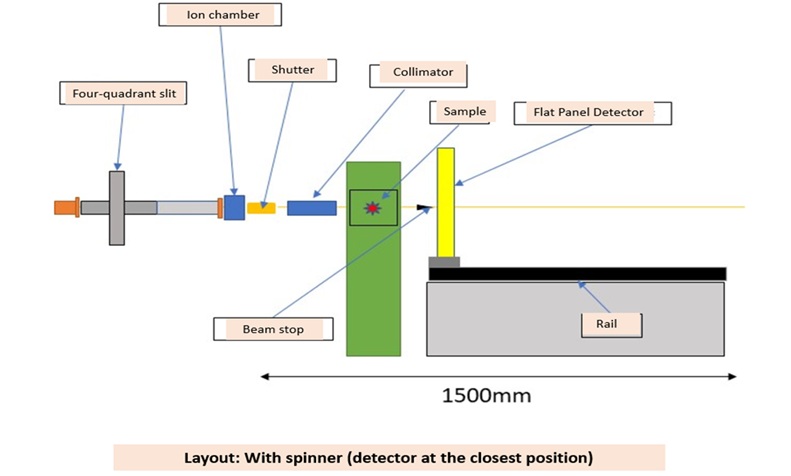

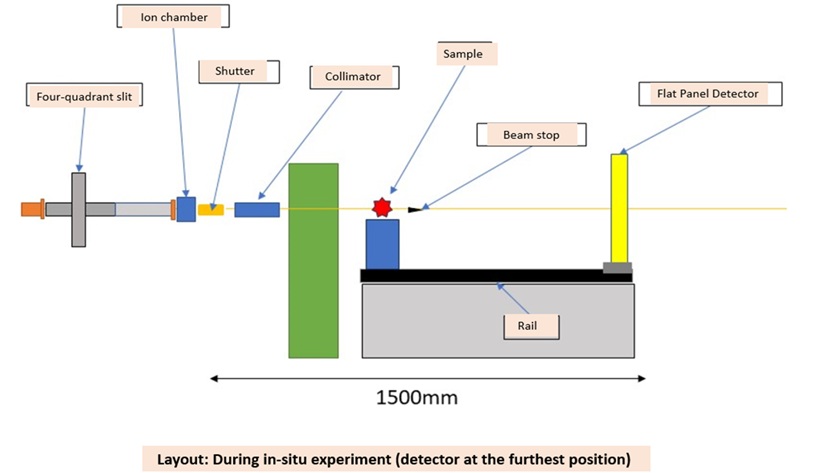

Layout

- With spinner (detector at the closest position)

-

- During in-situ experiments (detector at the furthest position)

-

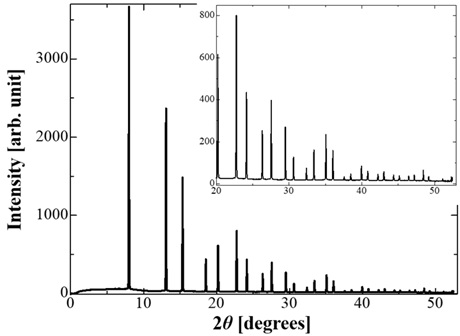

Measurement Examples

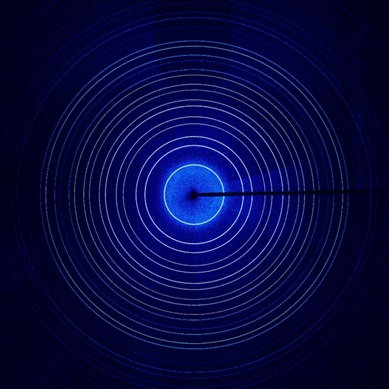

- Si powder diffraction pattern

-

28.5 keV

Sample - Detector distance 235 mm

5-second exposure

* Analysis of powder diffraction data obtained by the flat panel detector

using the Rietveld method is currently under consideration.

(Please contact a staff member for details.)

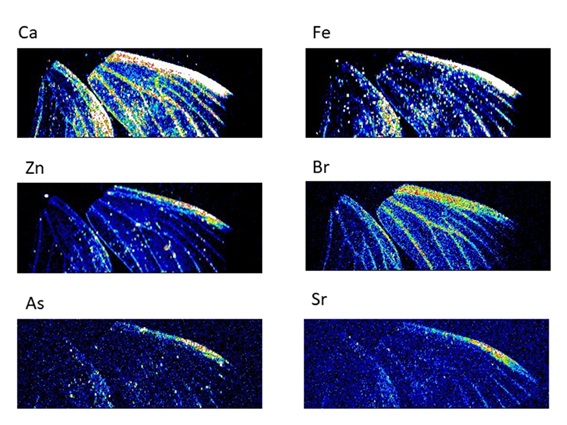

- Fluorescent X-ray elemental mapping of a moth's wing

-

17.5 keV

Horizontal 71 µm

Horizontal 300 points with a vertical 100 µm steps

Mapping 100 µm vertical points (33,000 points in total)

1 second accumulation per point

Total measurement time 660 minutes