BL08W XAFS SAMPLE MAKING

Table of Contents

- Powder sample

- Pellet sample

- Liquid sample

- Large sample(Bulk Materials, Thin-Film Substrates, etc.)

- Sample Preparation Example Download Link

Powder Samples

Required Materials

Carbon tape

Weighing paper

Tweezers

Spatula

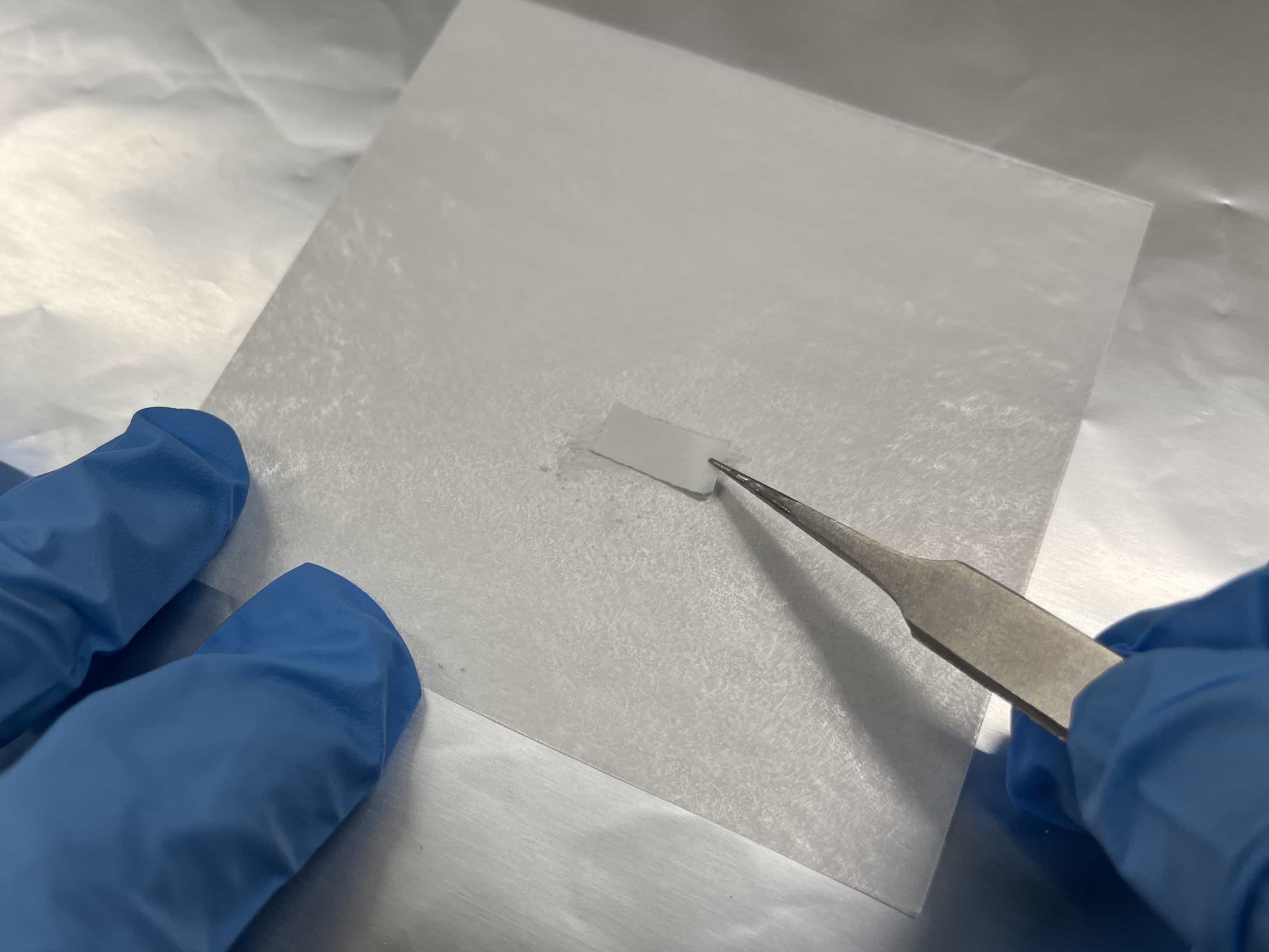

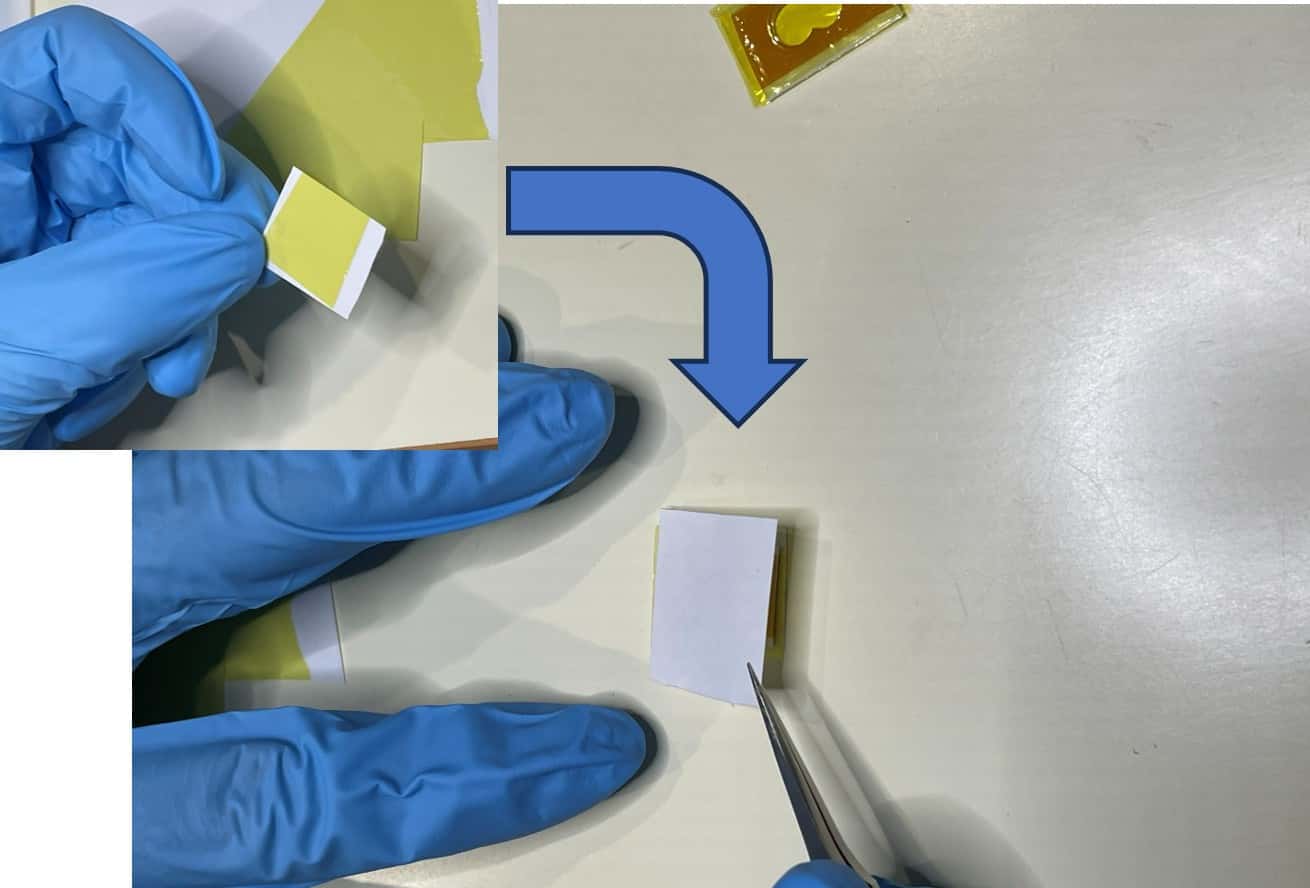

①Cut the carbon tape and place it with the release liner facing downward.

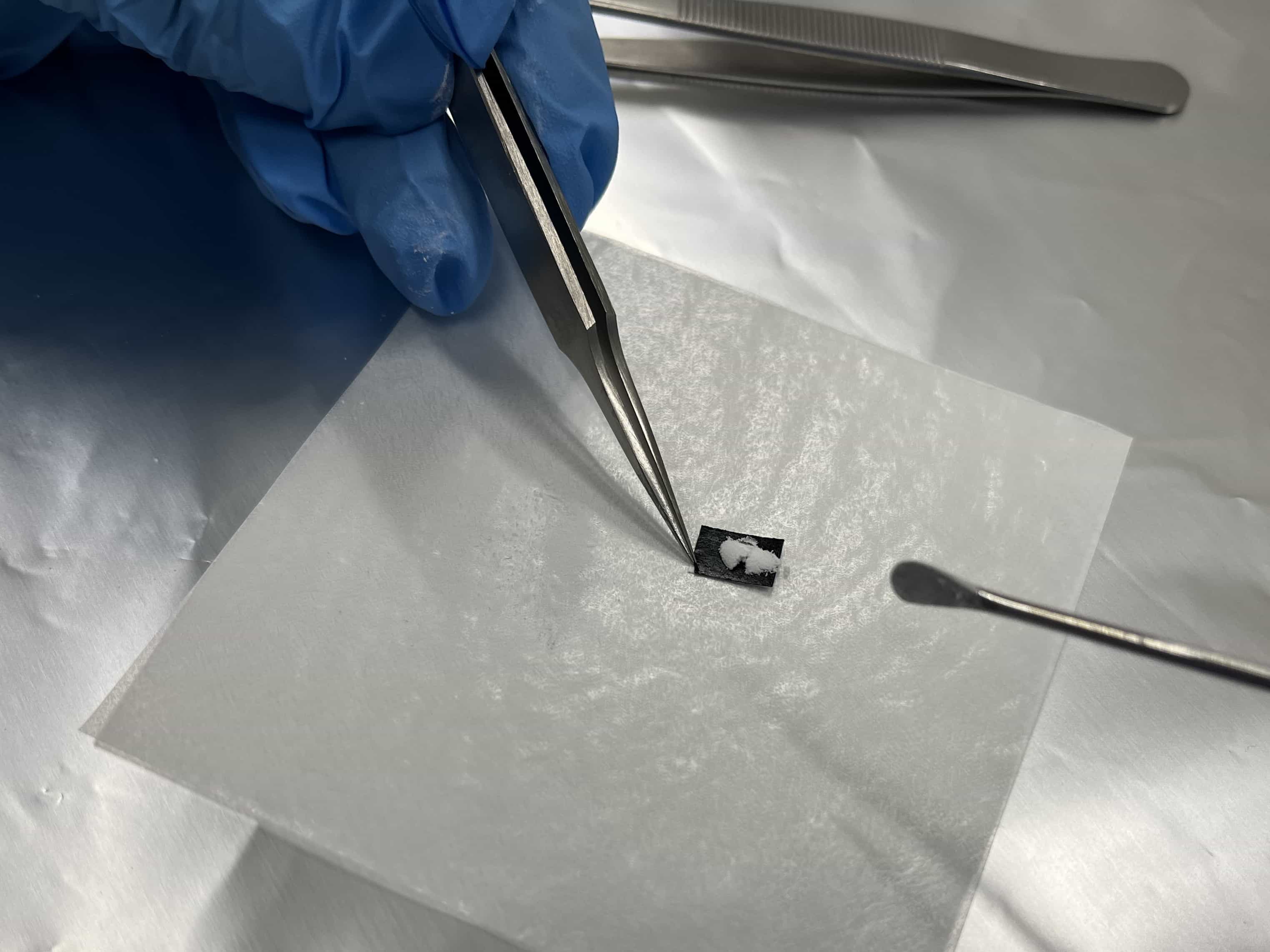

②Place the sample onto the tape.

③Level the sample using the flat edge of the spatula.

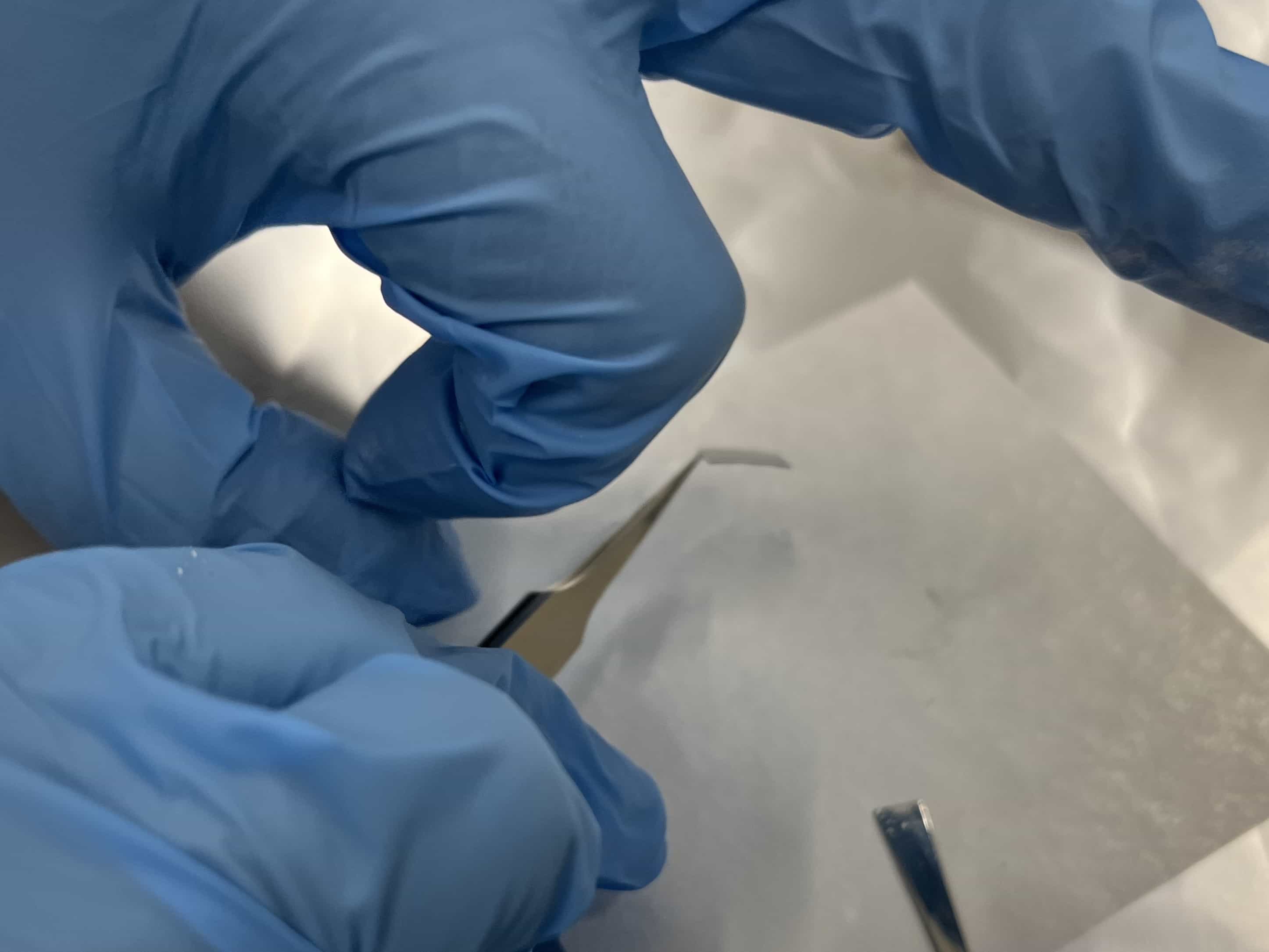

④Gently tap to remove excess sample.

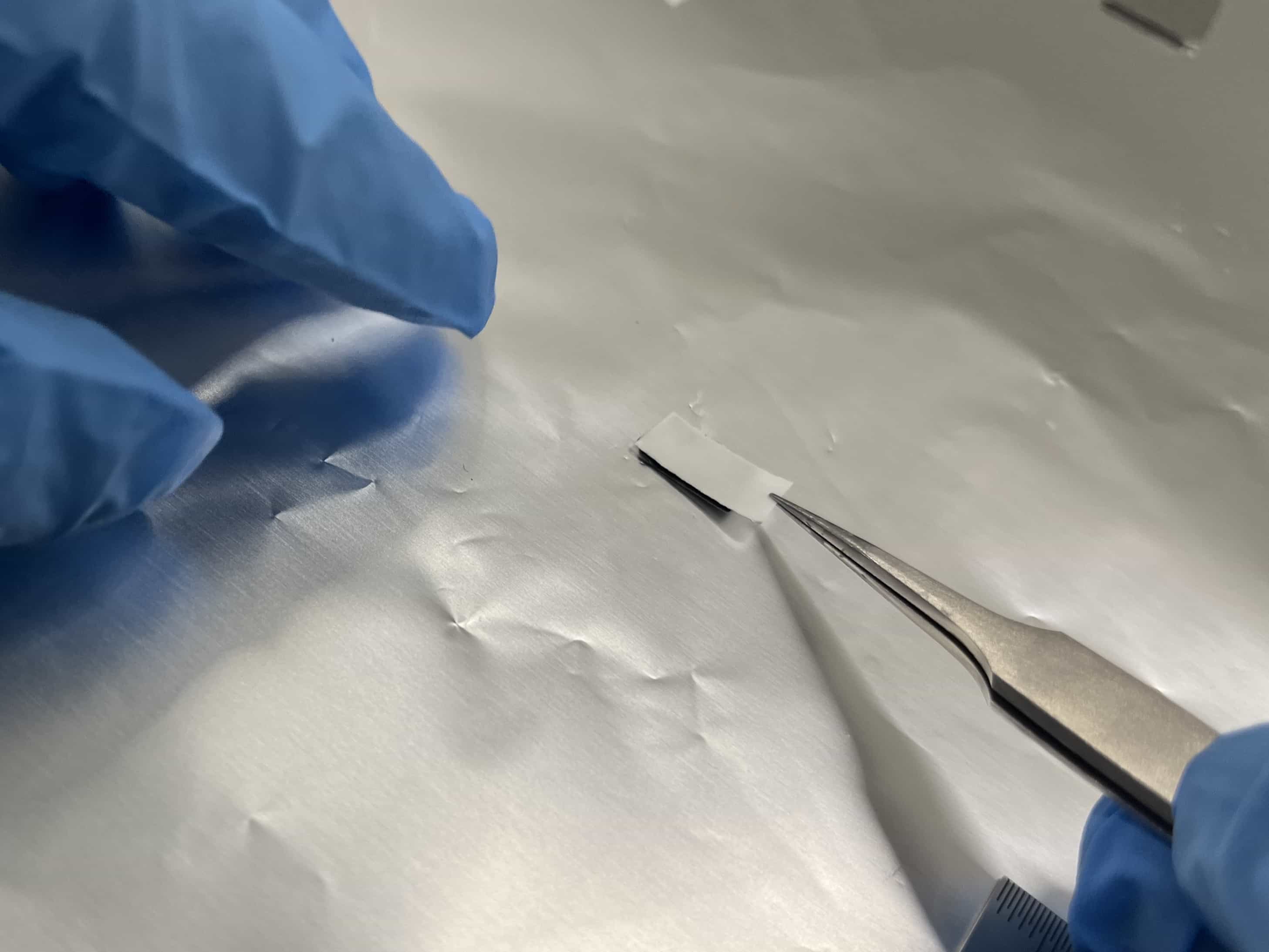

⑤Peel off the release liner.

⑥Attach the tape to the sample plate (BL equipment).

⑦Final setup.

⑧When using a slide mount for ambient conditions.

⑨When using an ion chamber for Conversion Electron Yield (CEY) measurements.

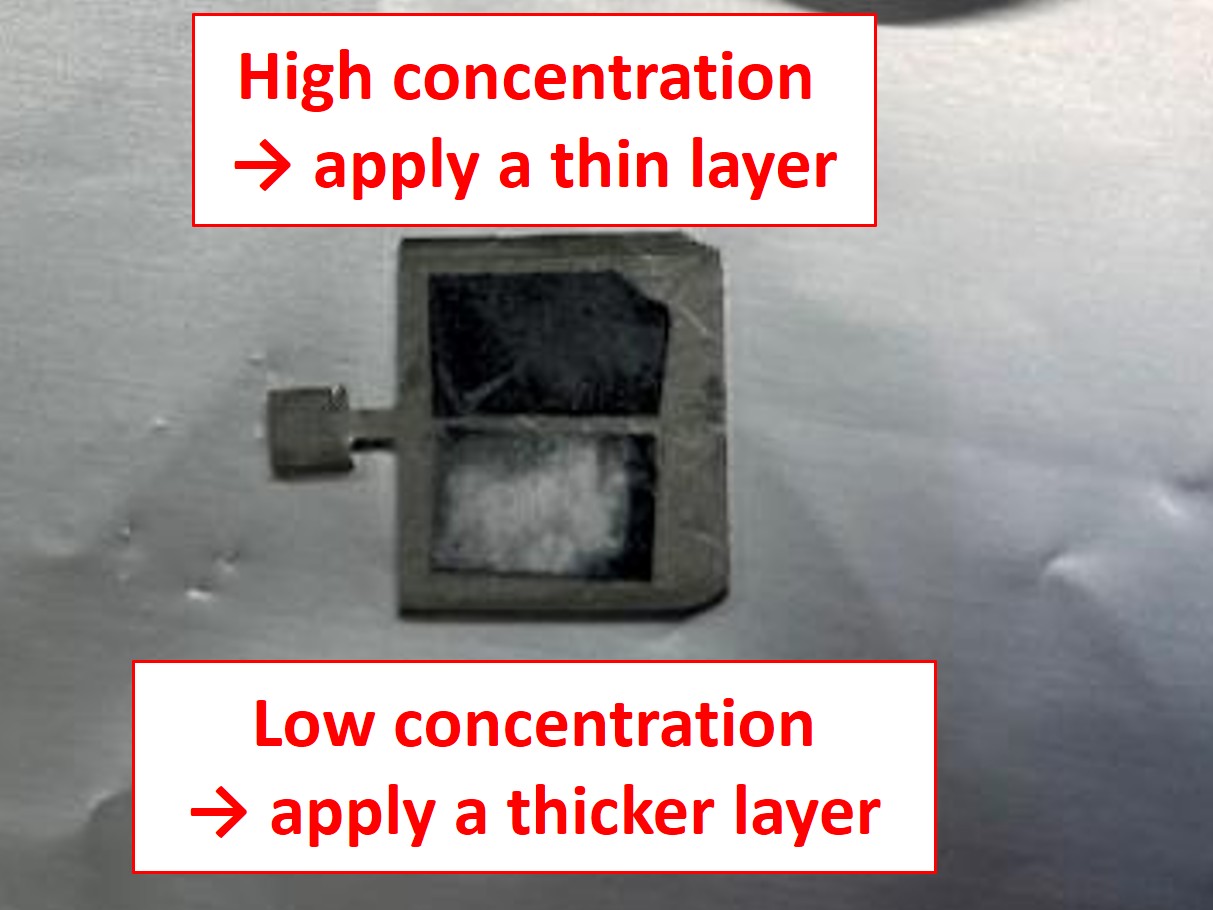

Ex:For High Sample Concentration

①Transfer the sample onto weighing paper.

②Lightly press the release liner onto the sample to allow a thin layer to adhere.

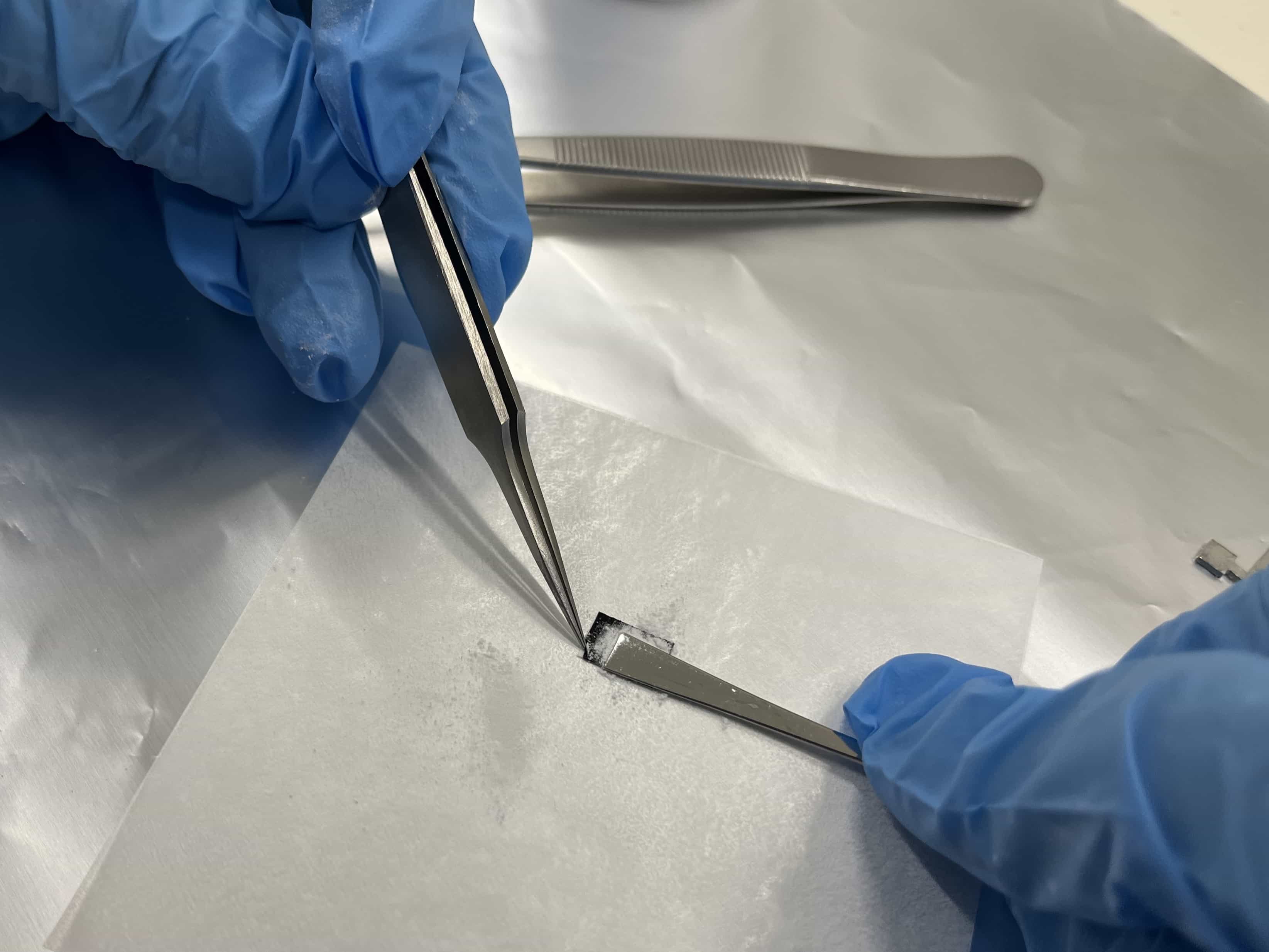

③Gently press the liner onto the carbon tape to transfer the sample.

④Attach to the sample plate.

Pellet Samples

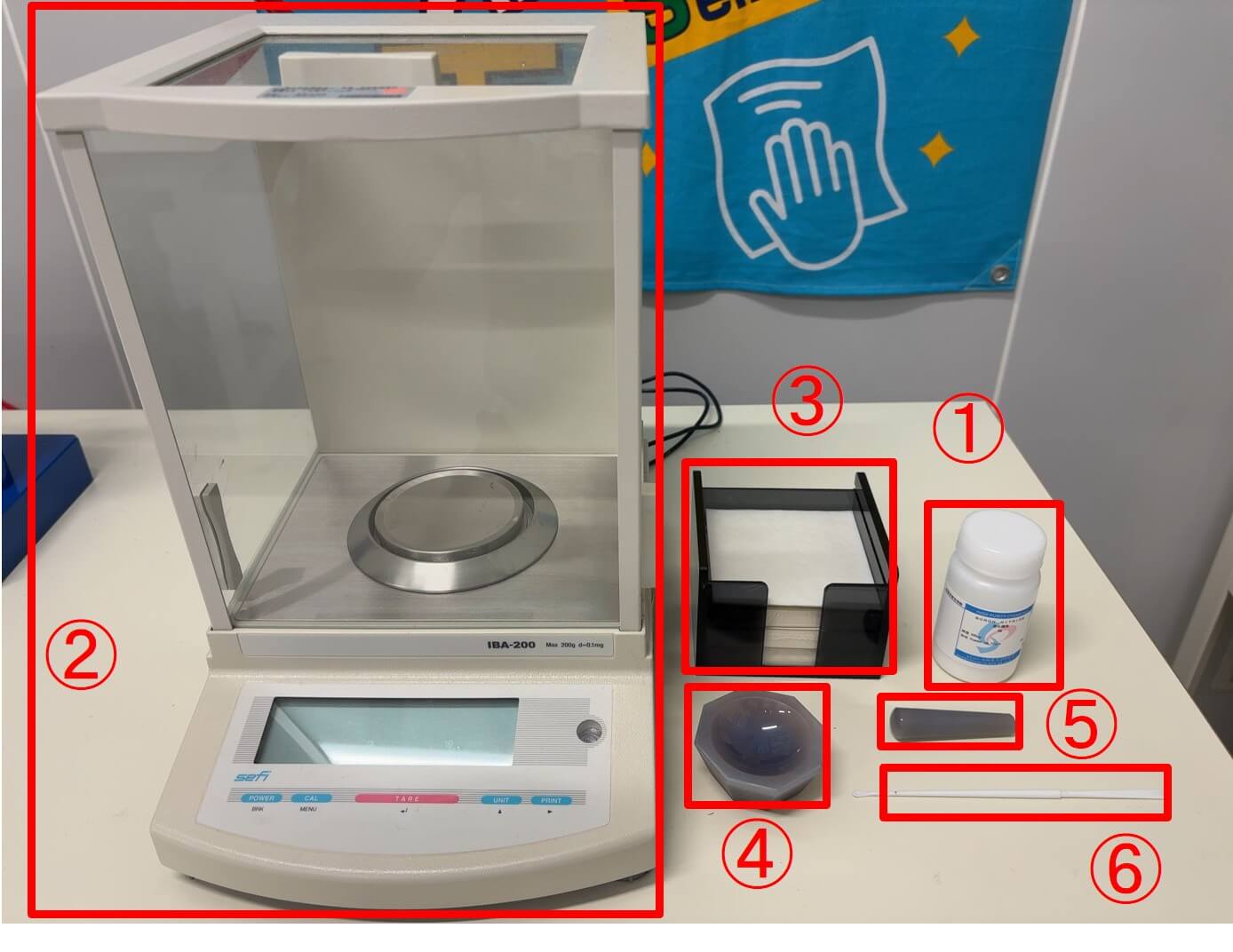

Required Materials

①BN(boron nitride)

②Analytical balance

③Weighing paper

④Mortar ⑤Pestle ⑥Spatula

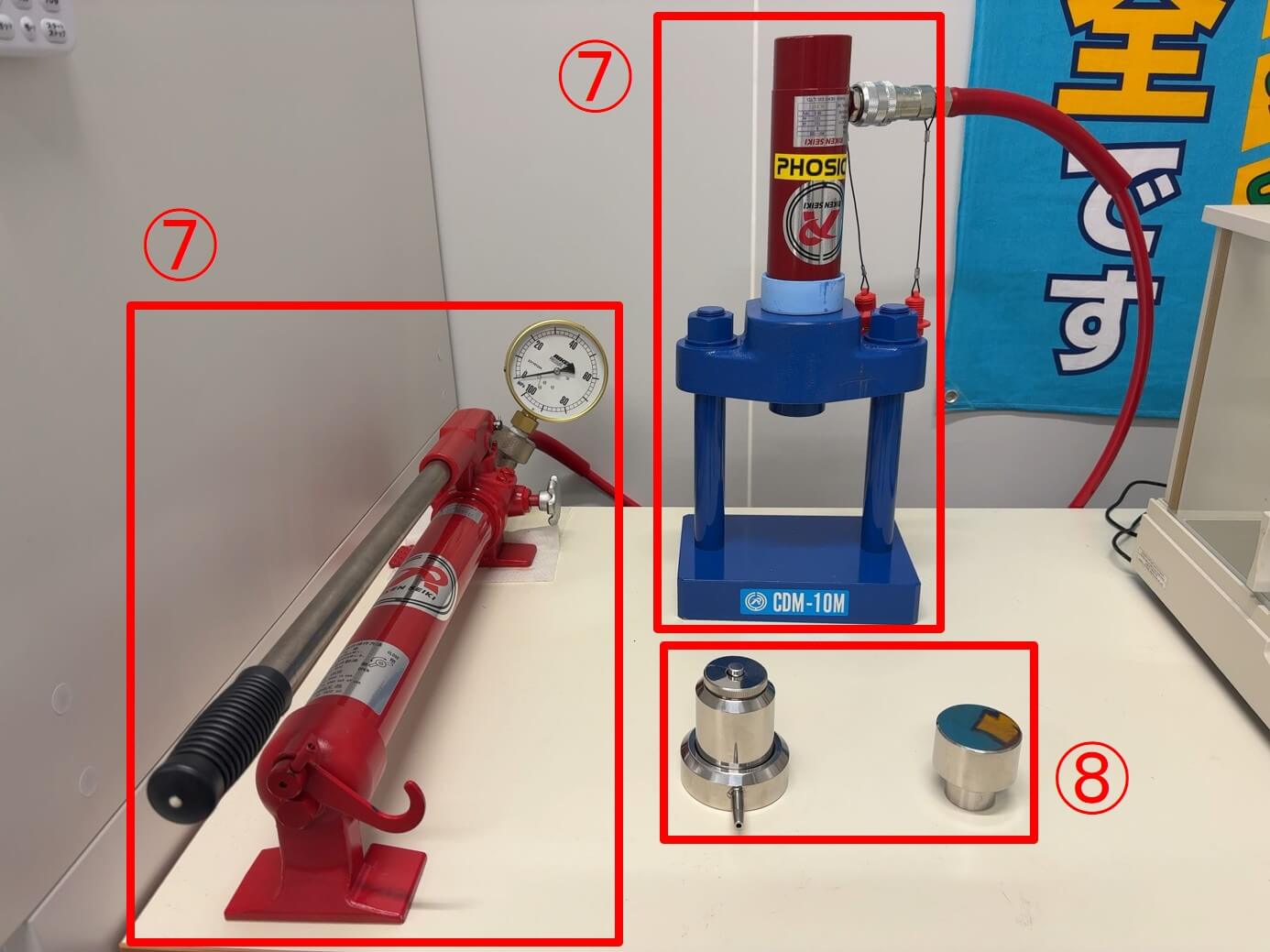

⑦Hydraulic press

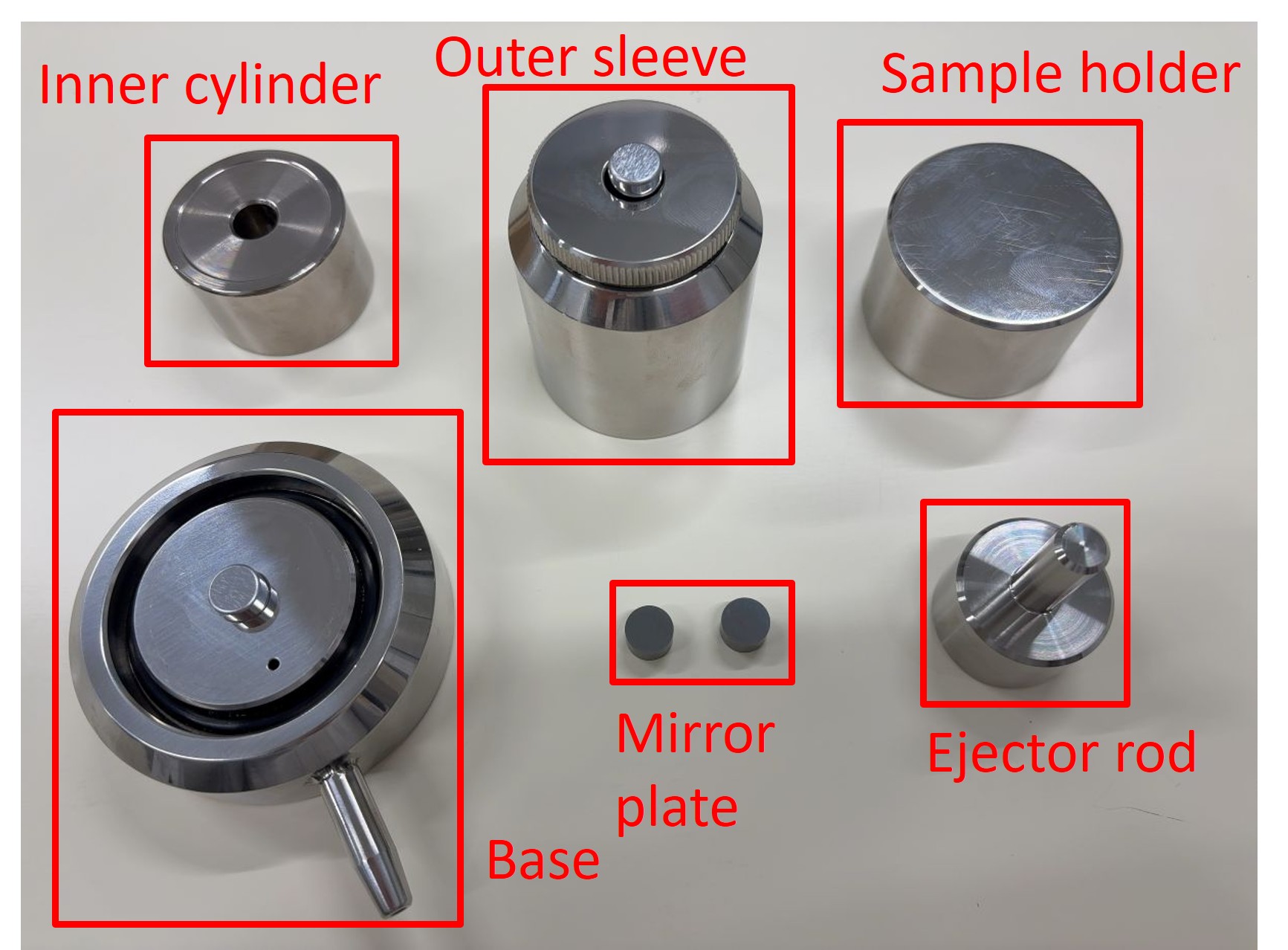

⑧Pellet die set

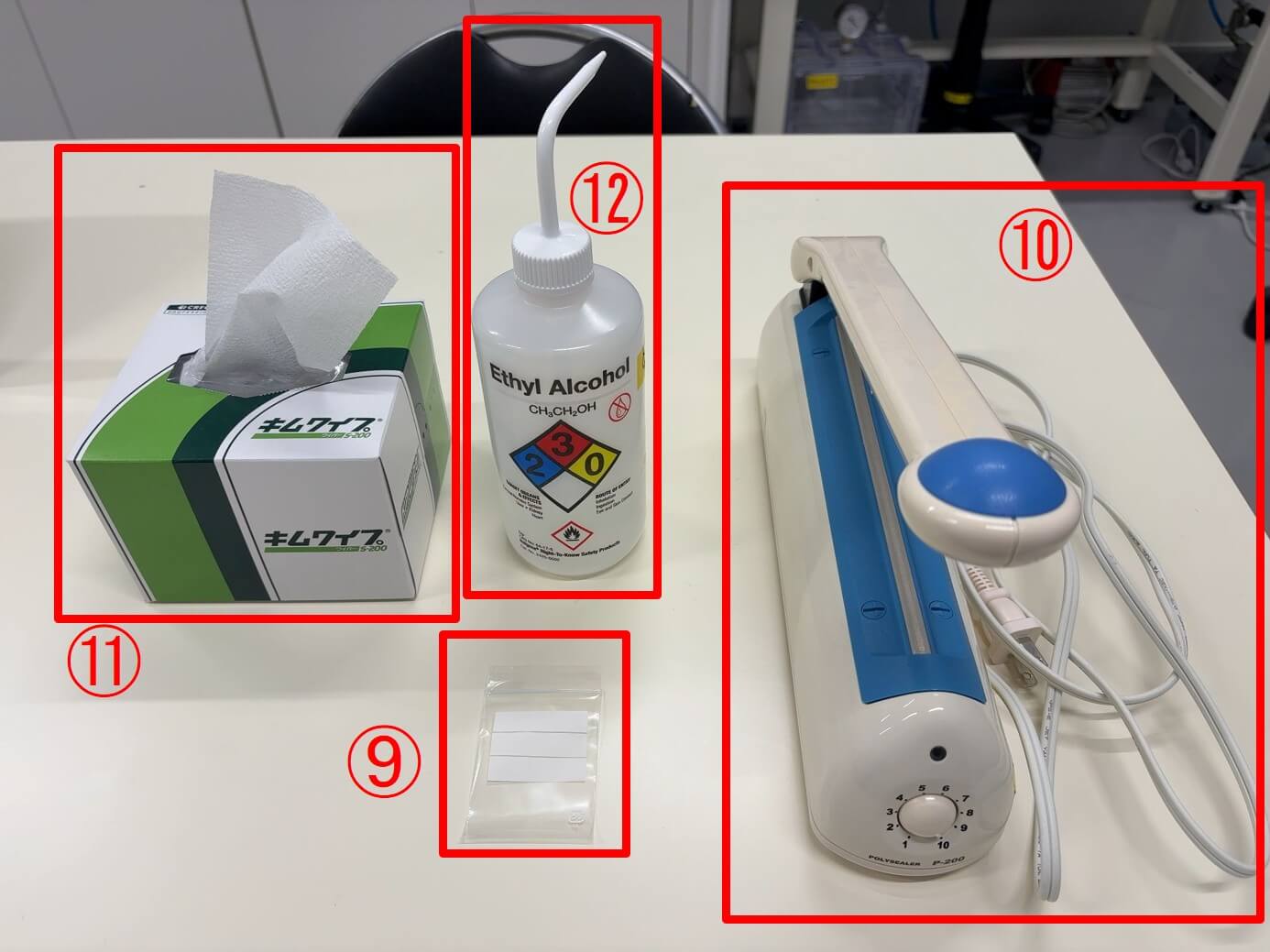

⑨Zip-lock bag ⑩Heat sealer

⑪Kimwipes ⑫Ethanol

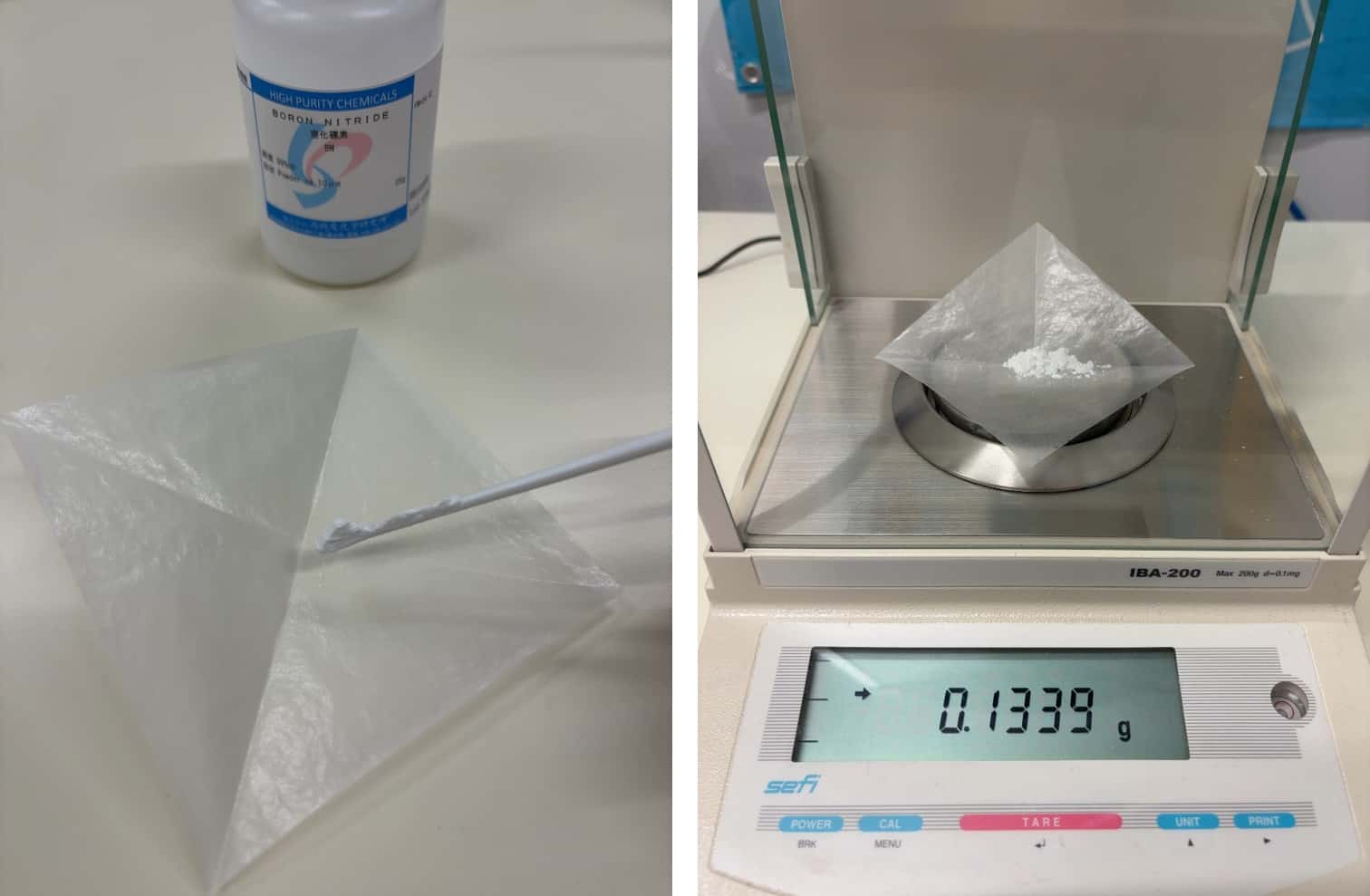

①Weigh the sample and BN using an analytical balance and dilute to an appropriate concentration.

(Reference: SPring-8 Industrial Application Promotion Office-Sample Preparation Guide Program)

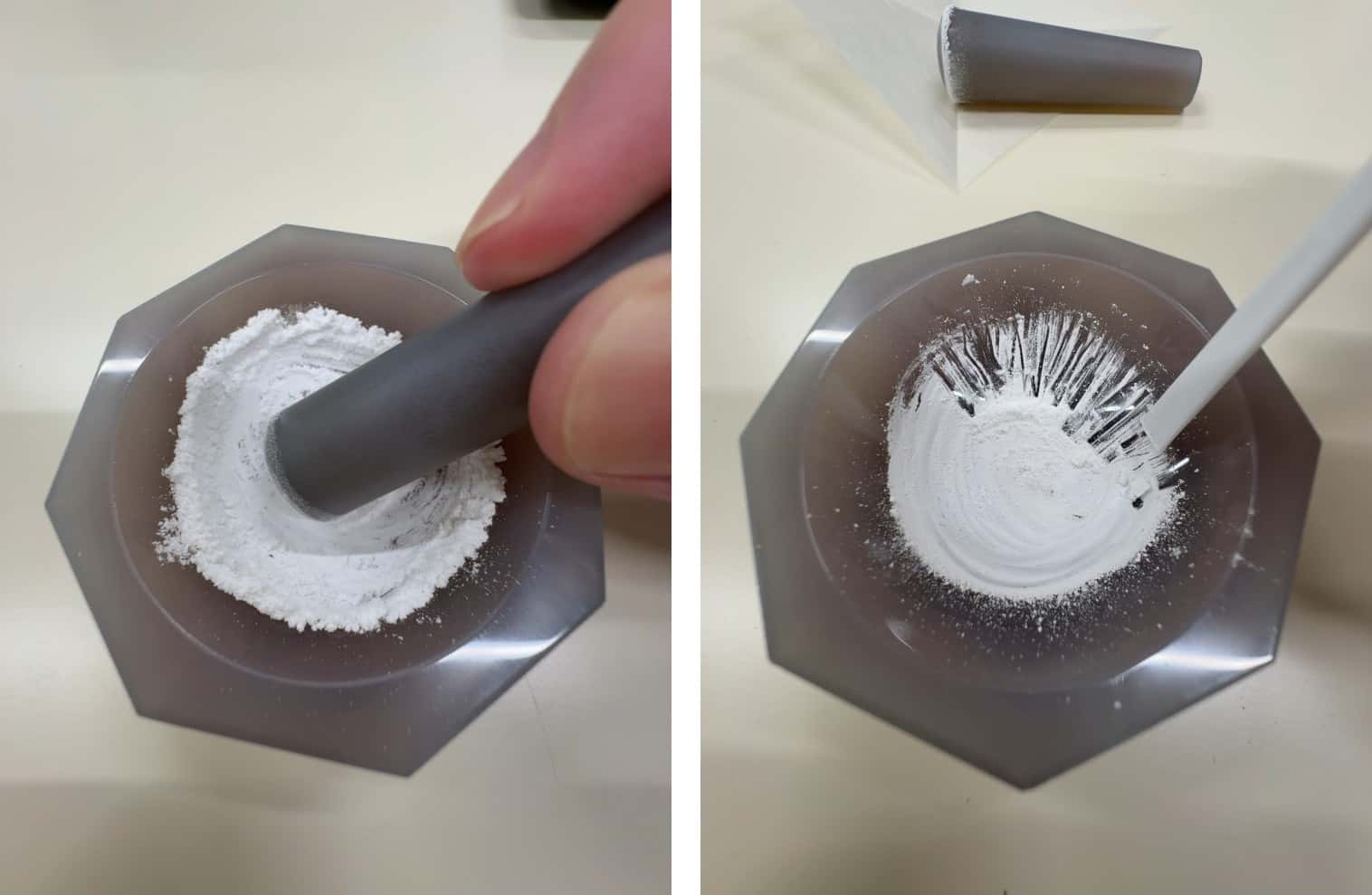

②Mix the sample in a mortar for approximately 20 minutes.

(Sample homogeneity has a significant impact on XAFS spectral quality)

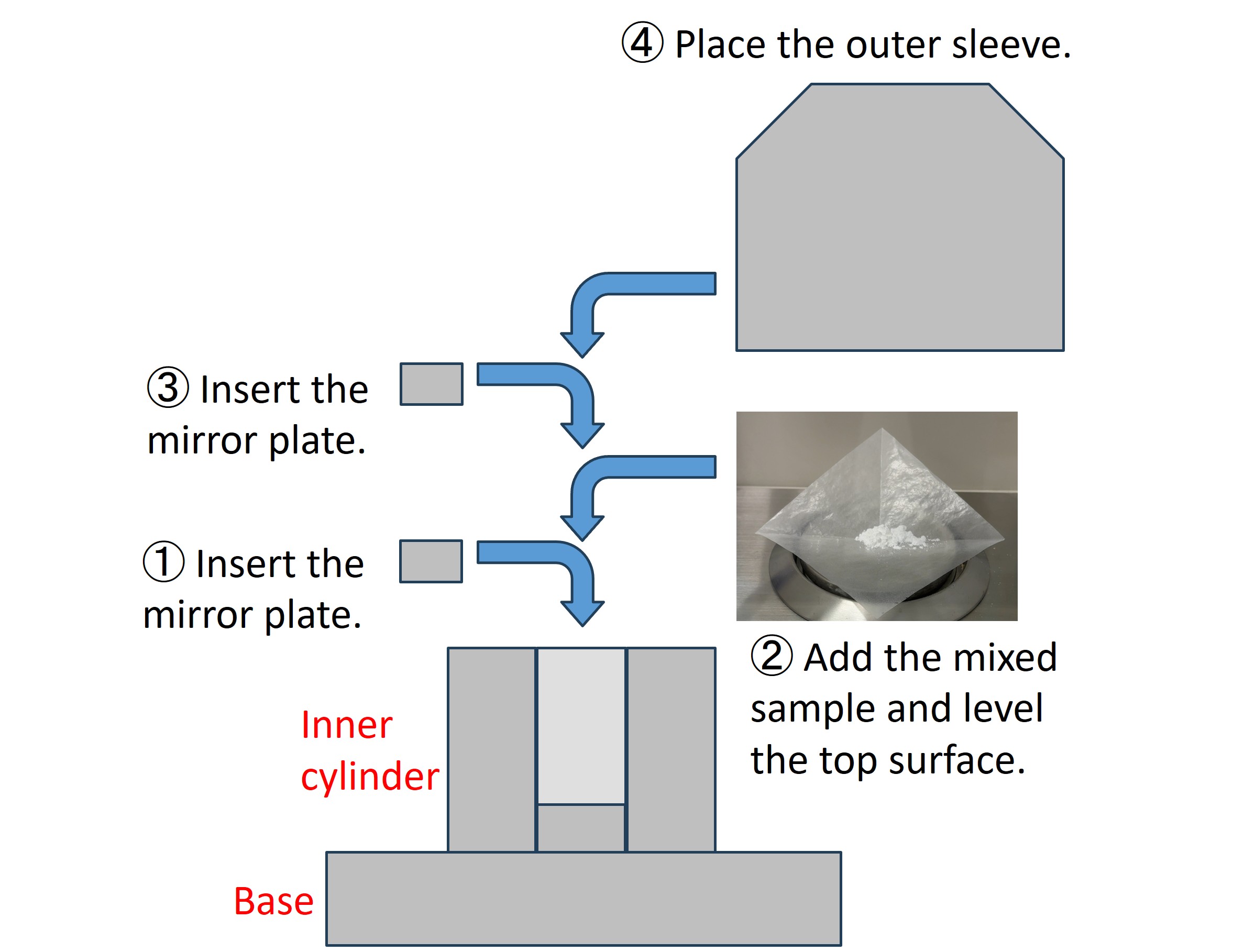

③Assemble the pellet die set.

④Apply pressure using a hydraulic press.

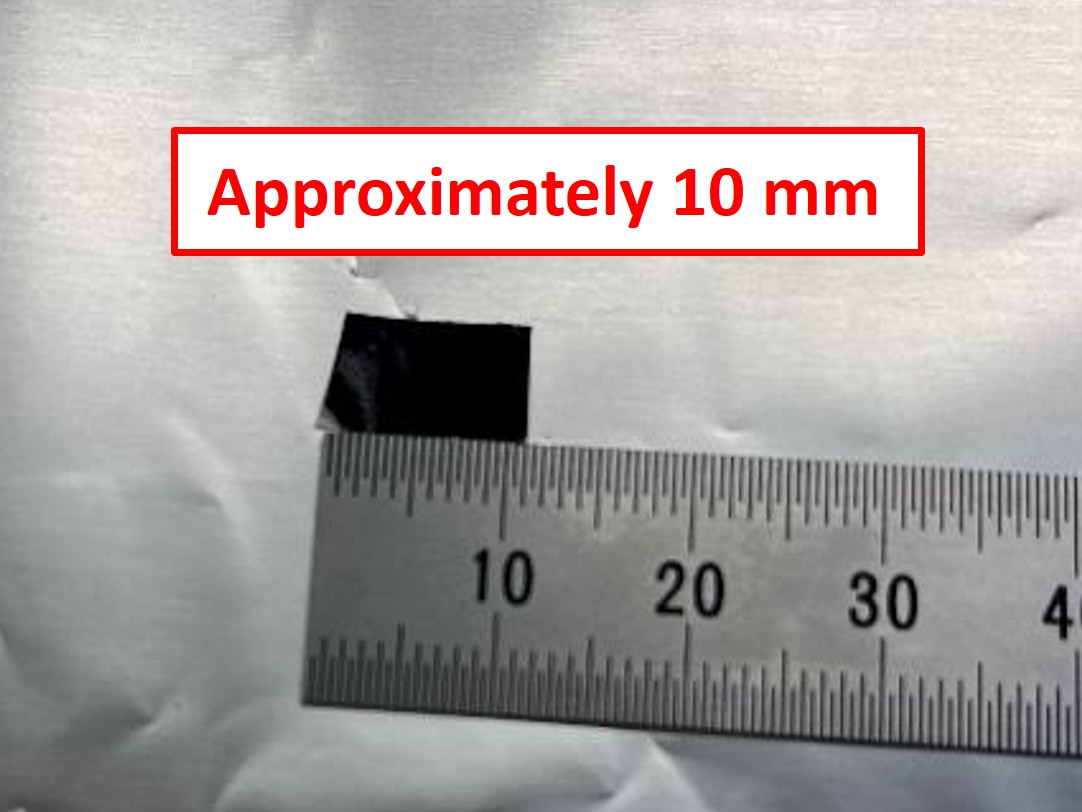

Example:Diameter: 10 mm, Thickness: 1 mm

Pressure: 10 MPa, Pressing time: 10 minutes

Adjust conditions as appropriate for the sample used.

⑤Reconfigure the pellet die set.

①Remove the outer sleeve and base, leaving only the inner cylinder.

②Insert the ejector rod into the top of the inner cylinder.

③Holding both the ejector rod and inner cylinder, carefully invert the assembly vertically.

④While holding the inner cylinder in place, attach the sample holder.

⑤Remove the pellet from the pellet die set.

①While holding the sample holder, apply slight pressure using the hydraulic press to gently push it in.

②Release the pressure and remove the pellet die set from the hydraulic press.

③Remove the sample holder.The pellet positioned between the mirror plates is exposed.

④Carefully remove the mirror plates to avoid cracking the pellet.

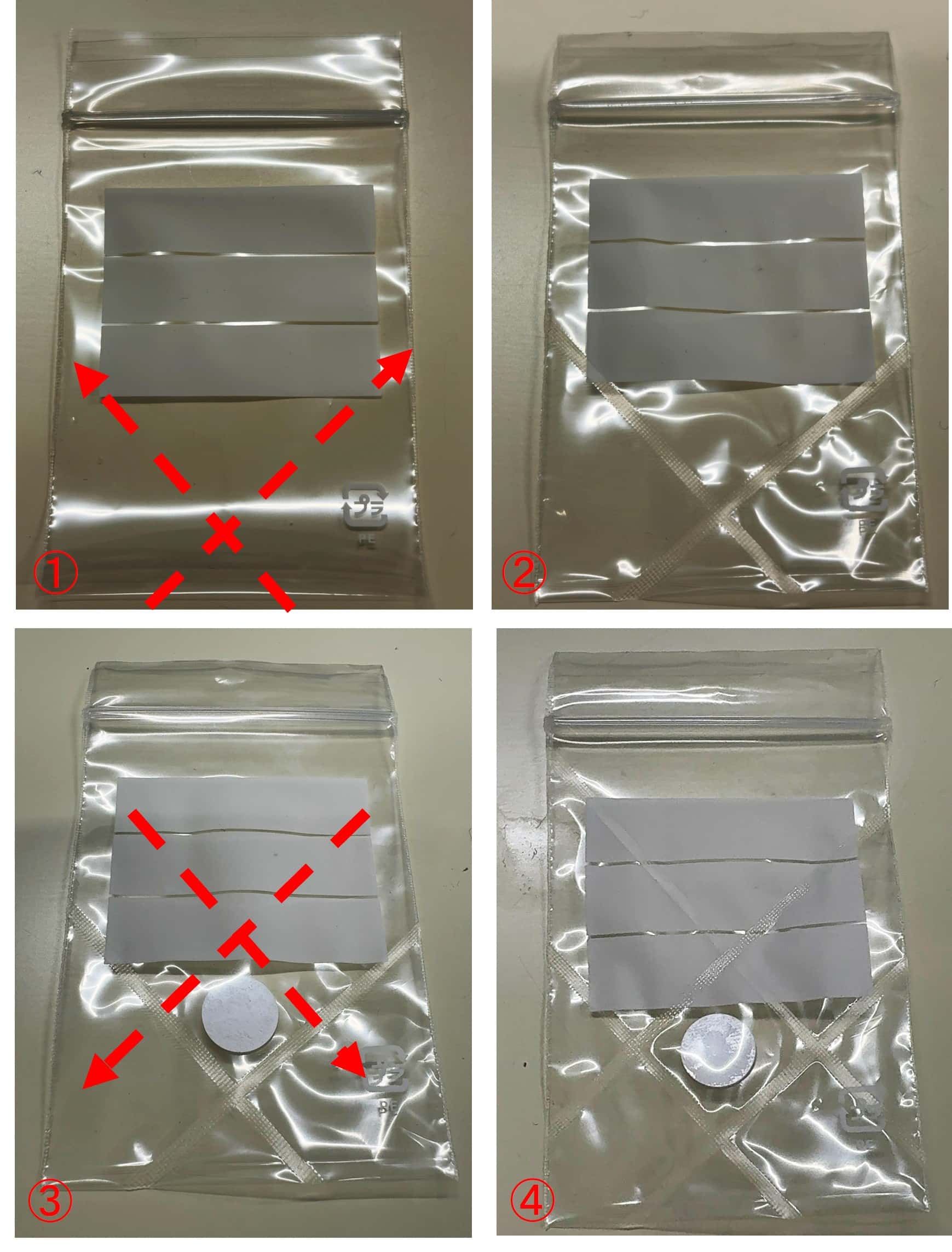

⑥Pellet Packaging

①Seal the lower half of the opening using a heat sealer.

②Place the pellet inside.

③Seal the upper half of the opening.

④Final setup.

Liquid Samples

Required Materials

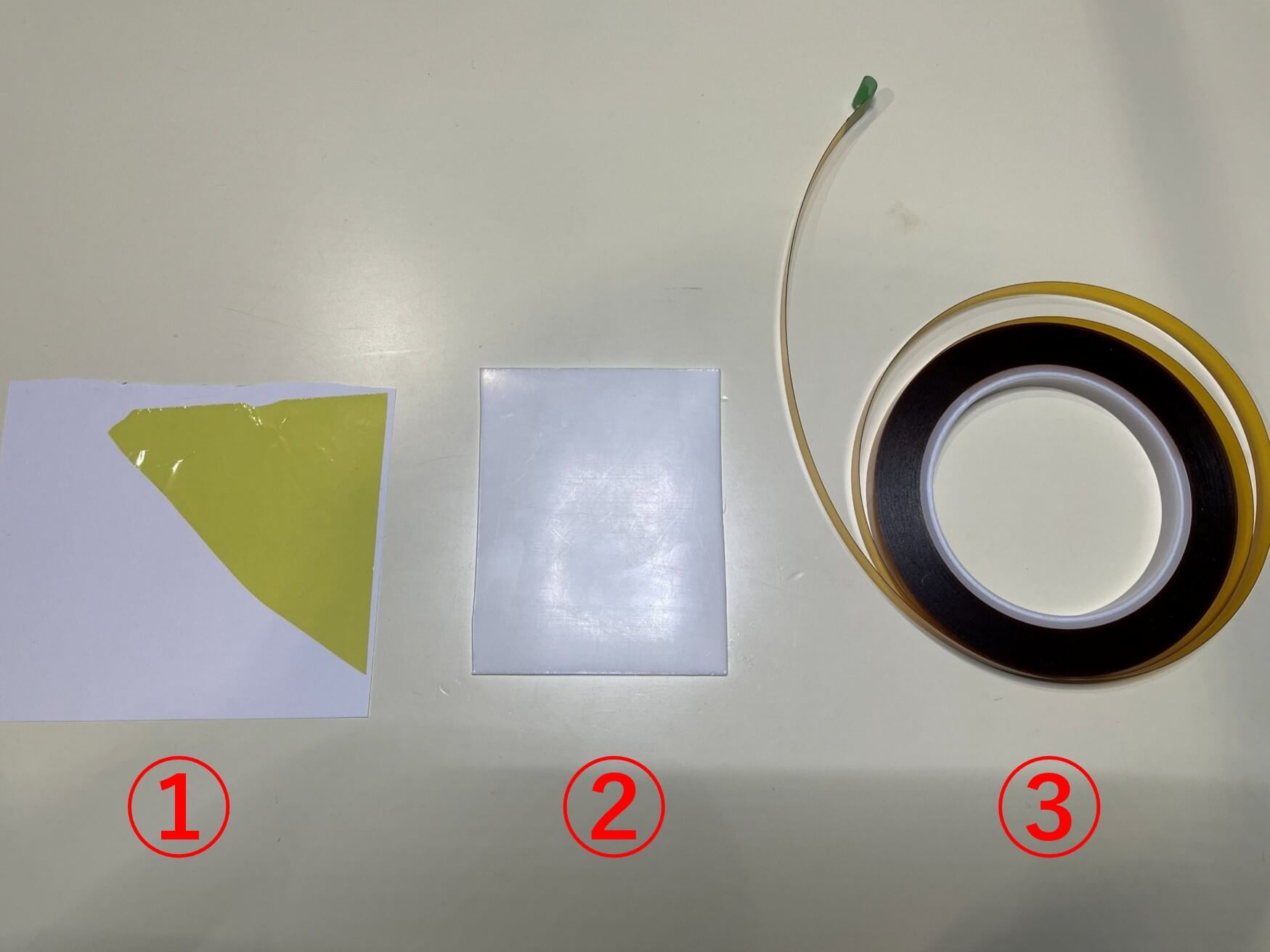

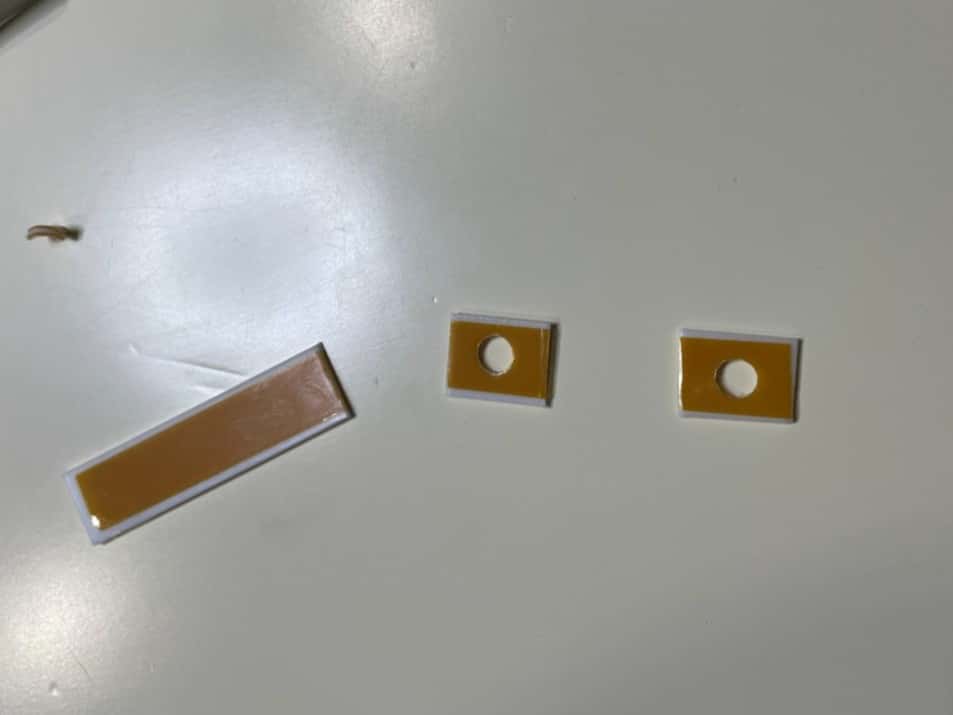

①Kapton film:5um

②Teflon film:1.0mm

③Double-sided Kapton tape:145um

Hole punch (5.5 or 7 mm diameter)

Sizes are for reference only. Adjust as appropriate for the sample used.

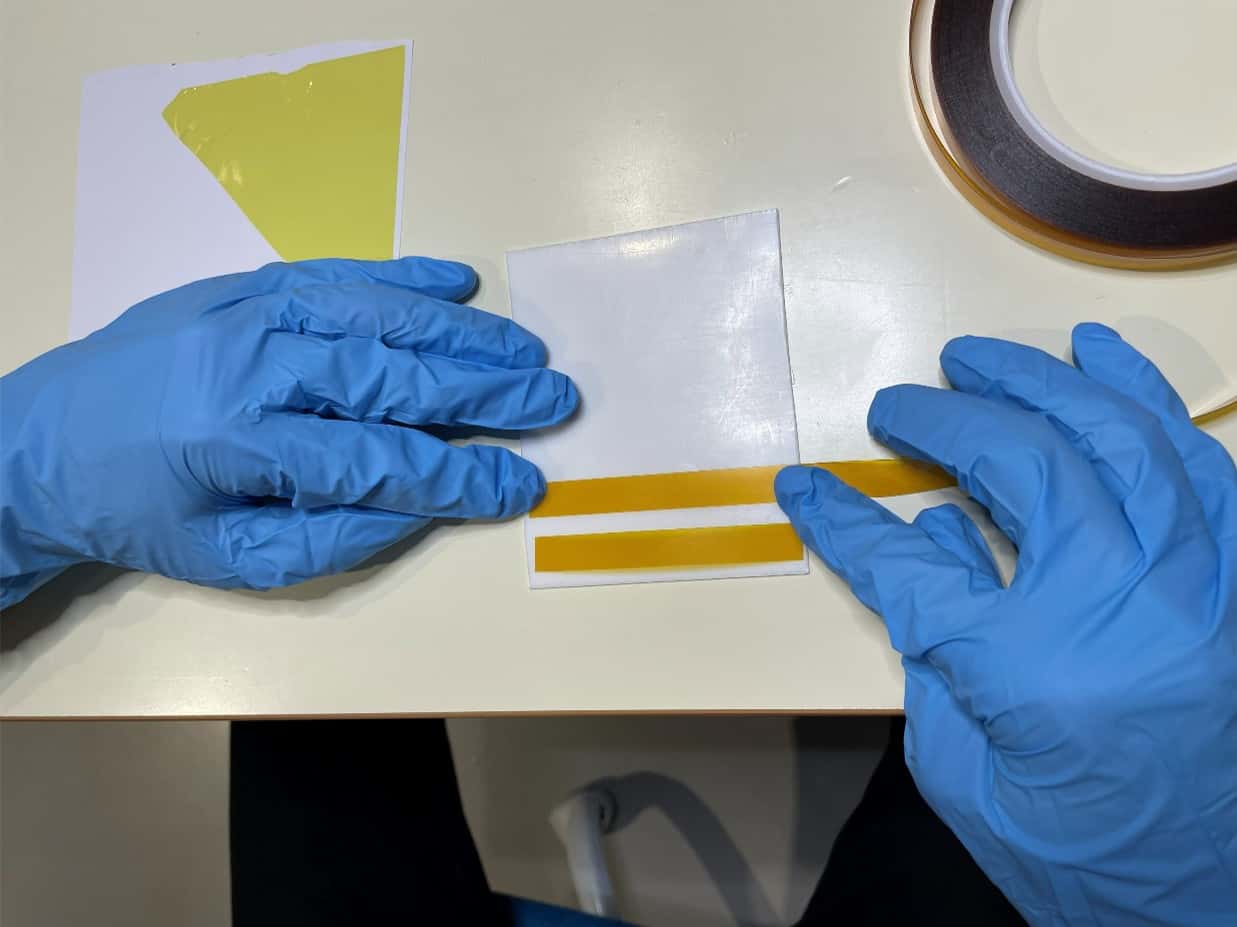

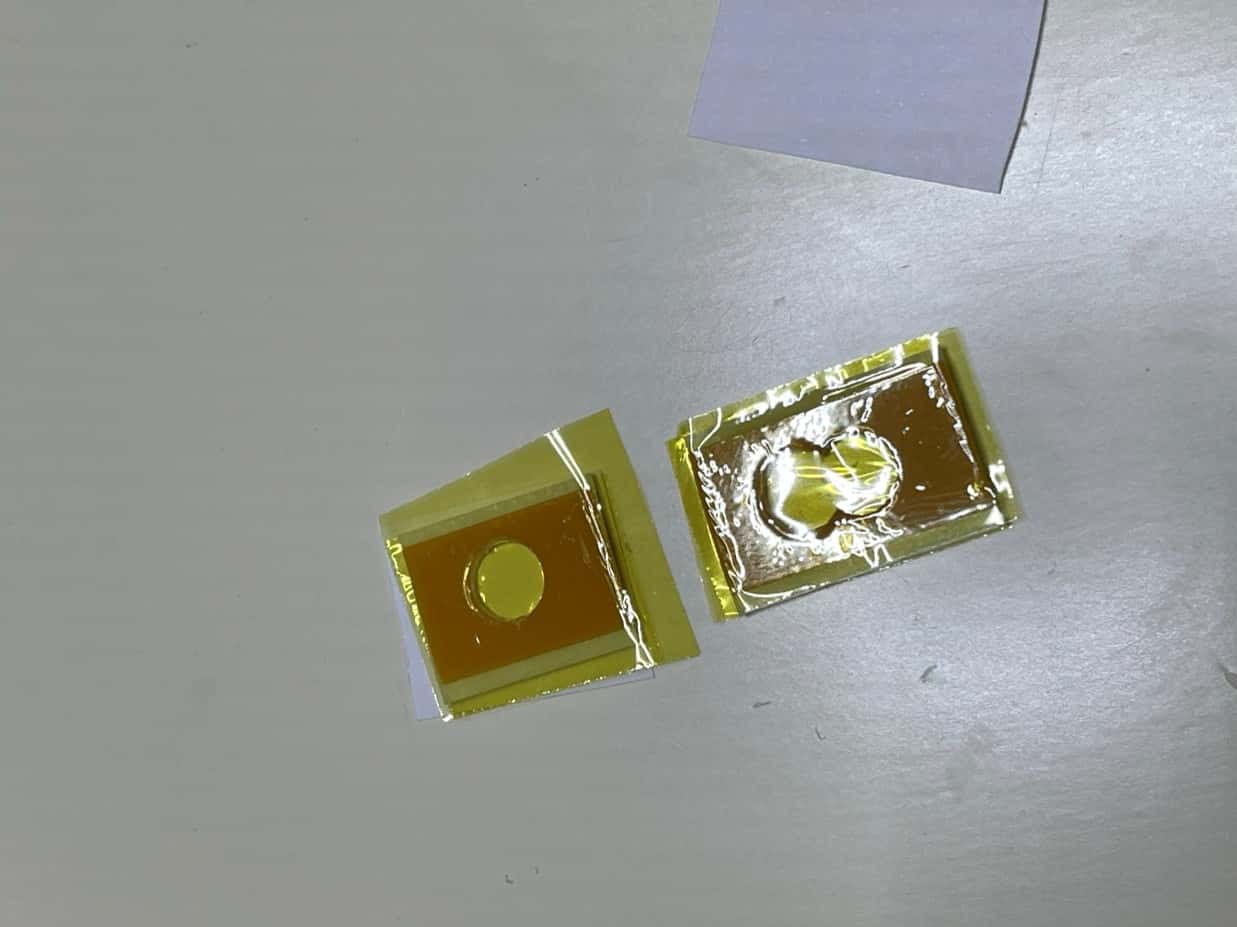

①Cut the double-sided Kapton tape into the required size.

②Peel off the transparent protective film from one side of the Kapton tape.

③Attach the Kapton tape to both sides of the Teflon film.

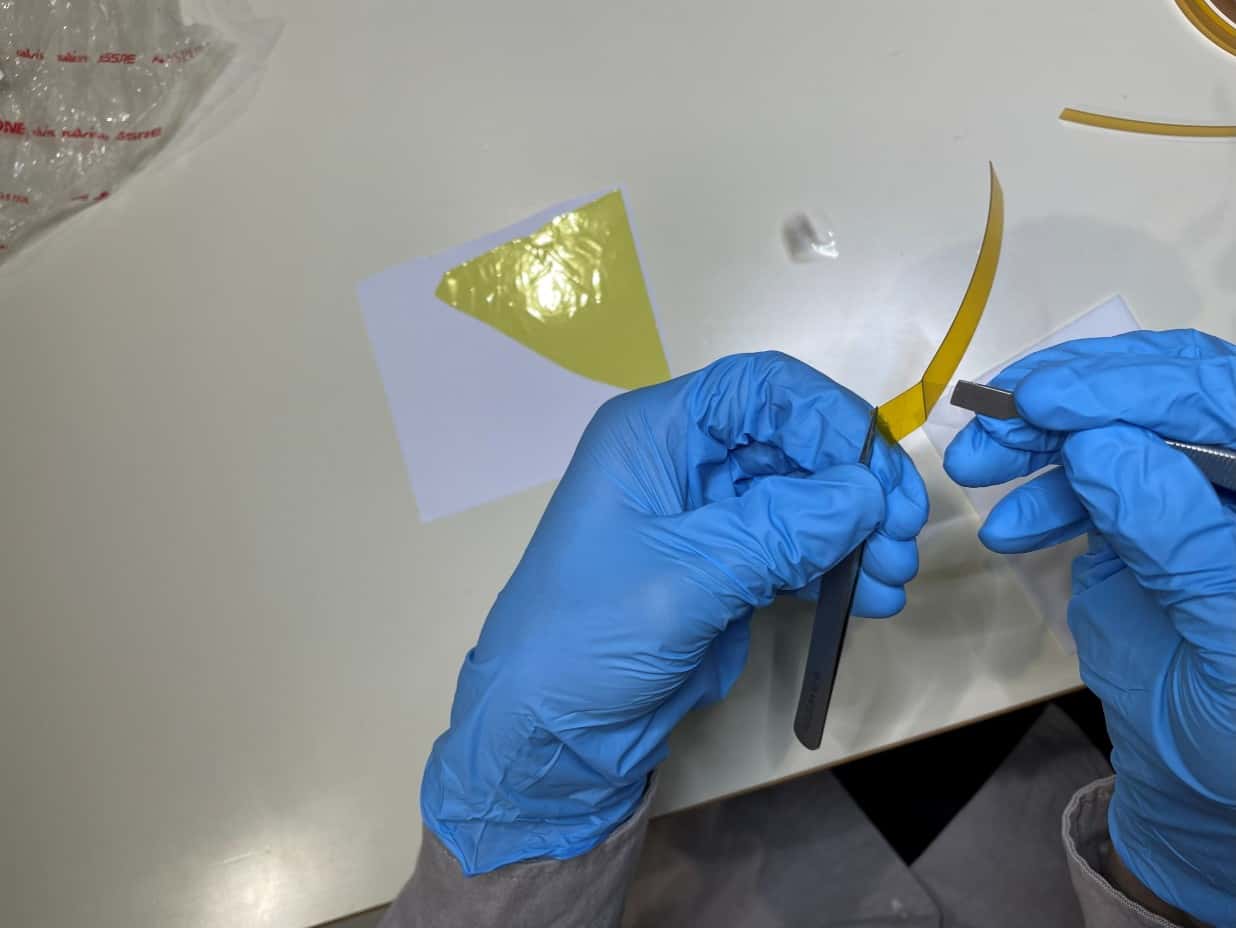

④Cut out the Teflon film with the attached Kapton tape to the desired shape.

⑤Punch a hole at the center of the Teflon film with attached Kapton tape (snowman-like shape).

⑥Cut out the cell structure.

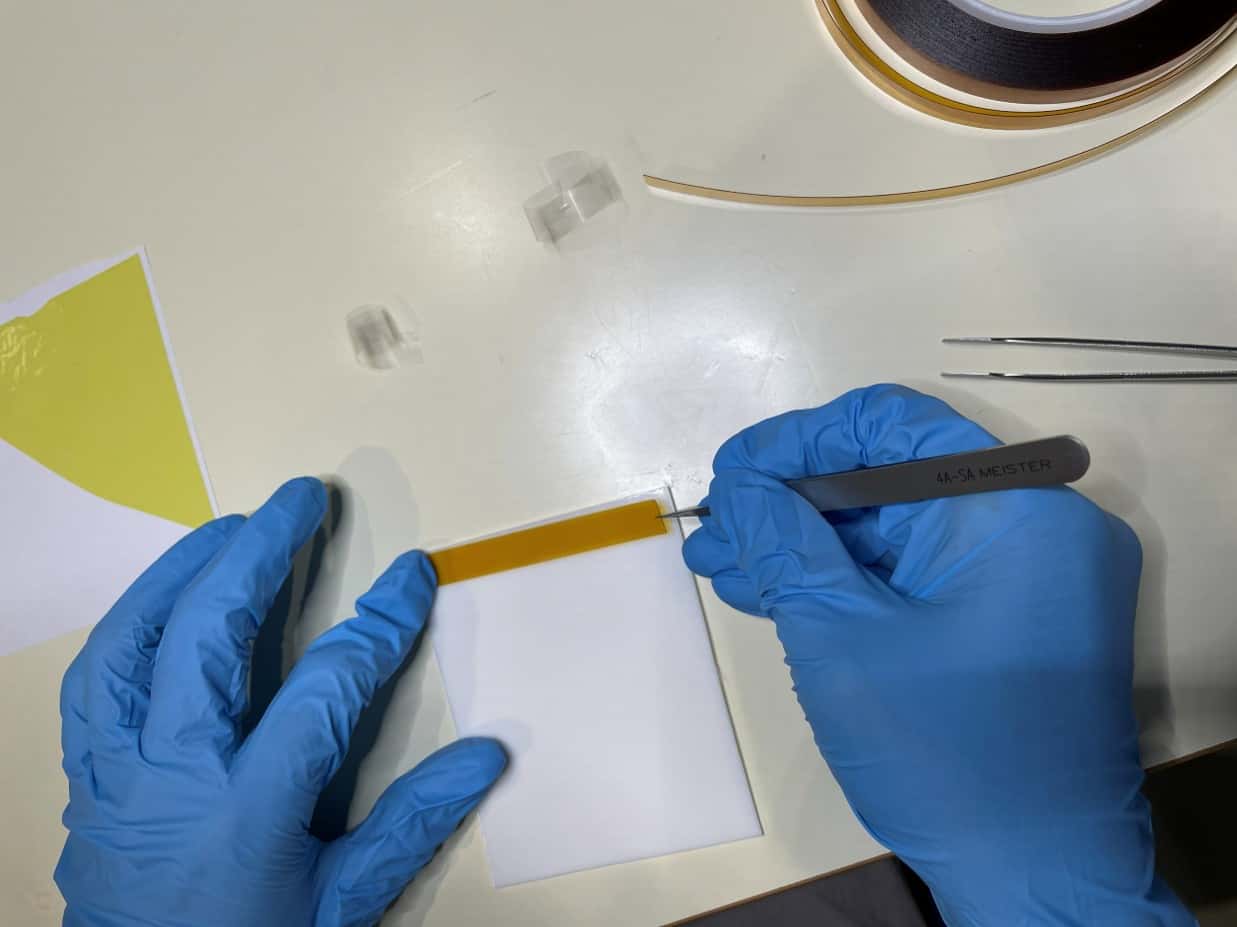

⑦Peel off the transparent protective film from one side of the Kapton tape on the cell.

⑧Attach the cell to the Kapton film to complete the empty cell before solution injection.

⑨Peel off the remaining transparent protective film from the Kapton tape.

⑩Inject the solution carefully to avoid overflow.

⑪Cover the filled cell with another Kapton film.

⑫Final setup.

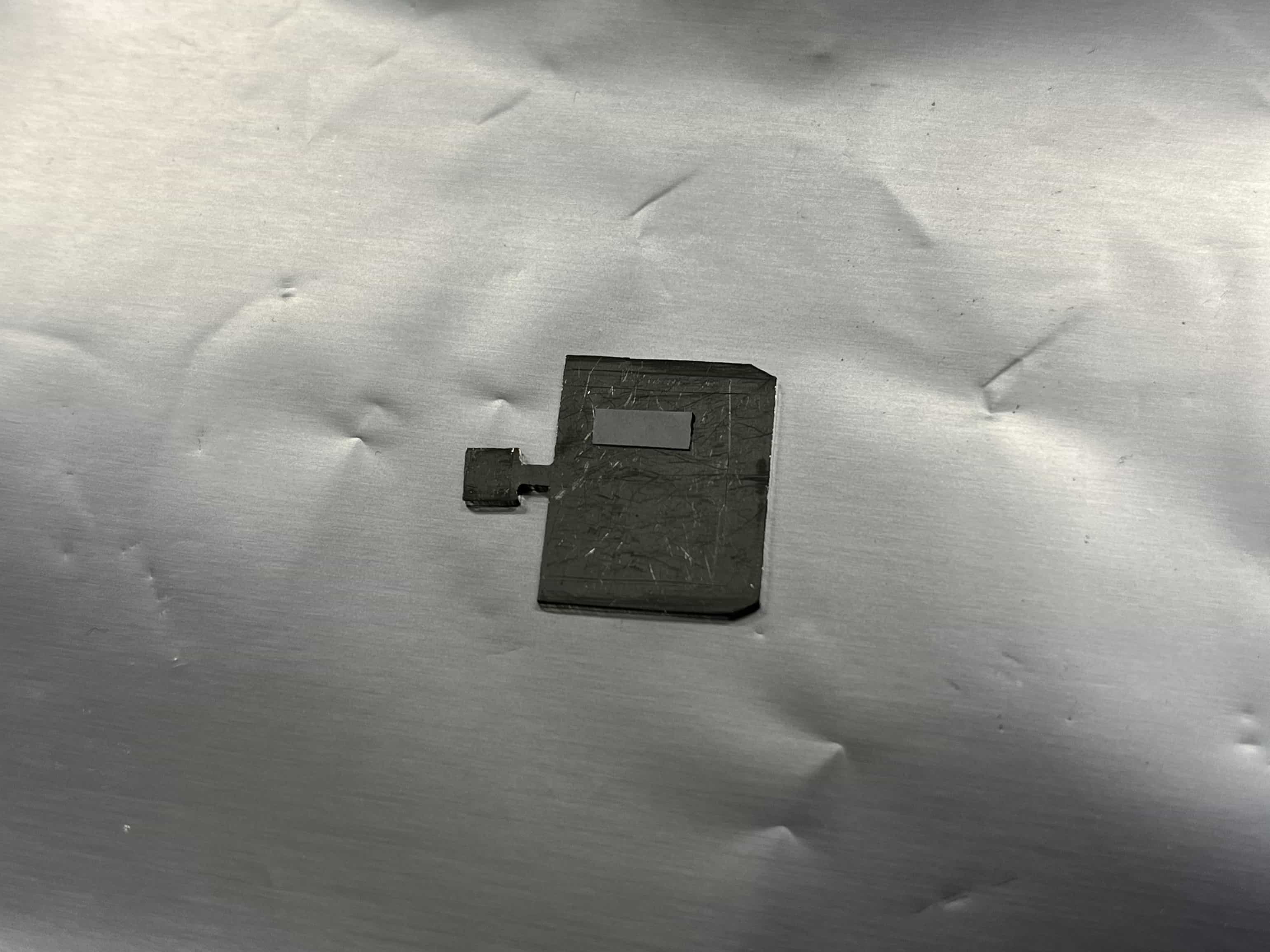

Large Samples(Bulk Materials, Thin-Film Substrates, etc.)

Required Materials

Carbon tape

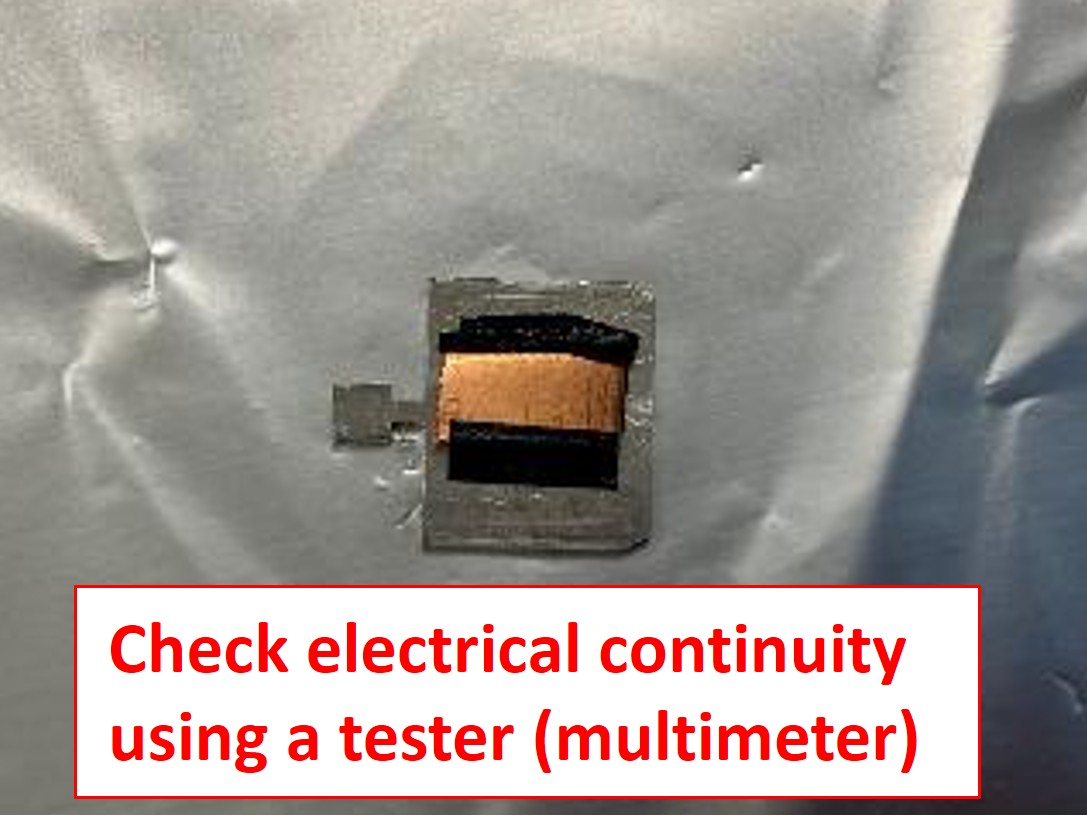

Tester (multimeter)

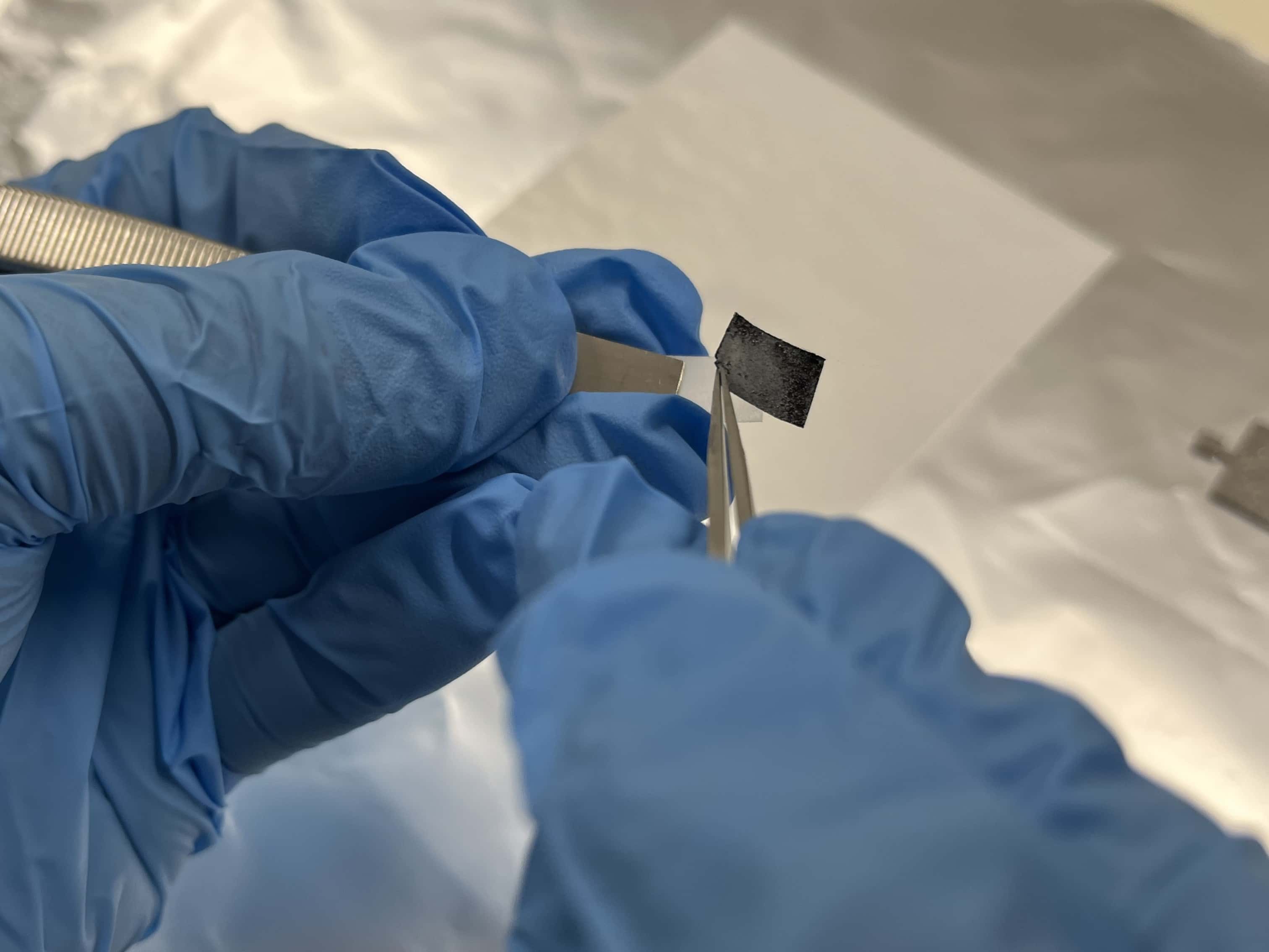

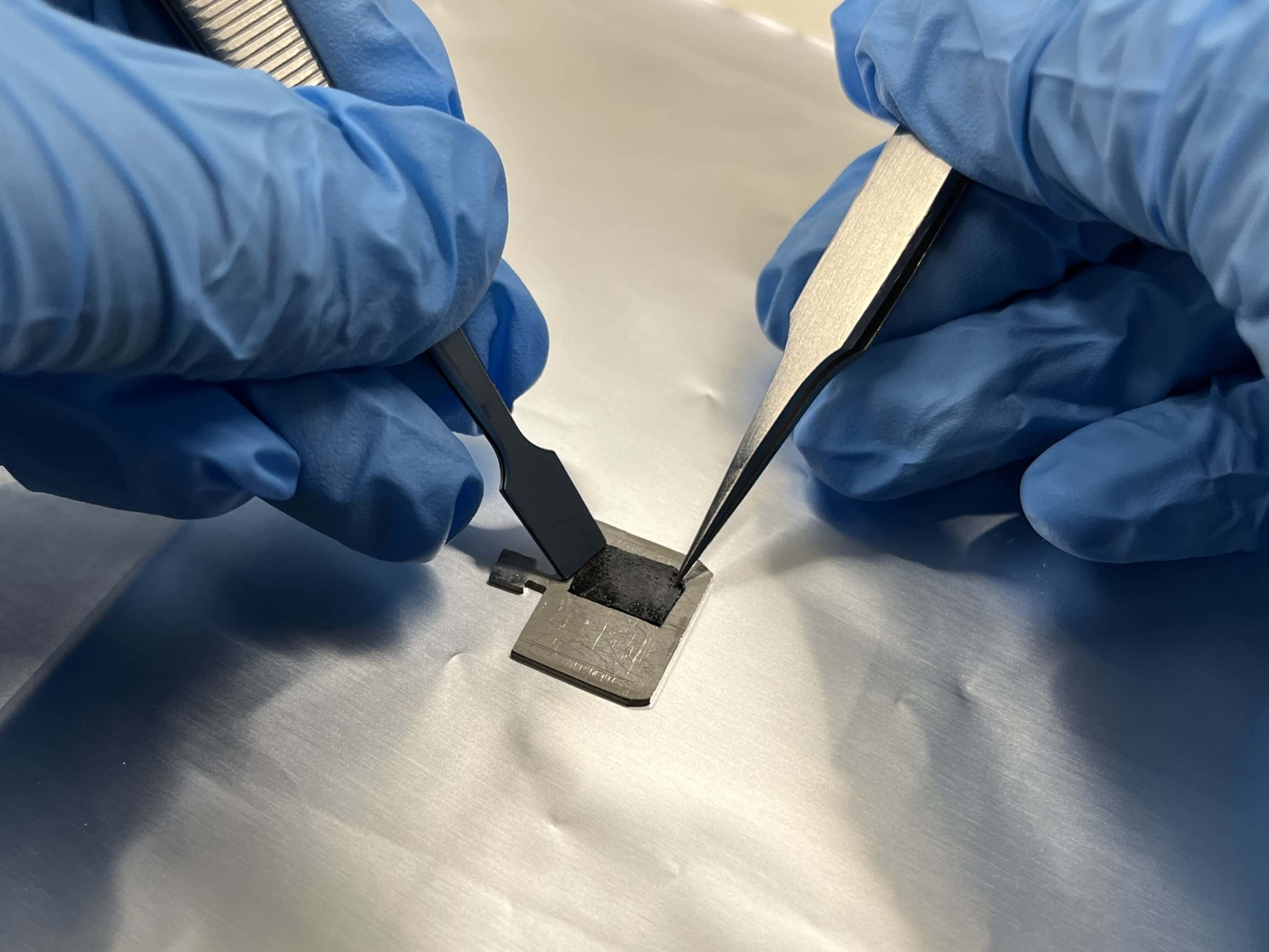

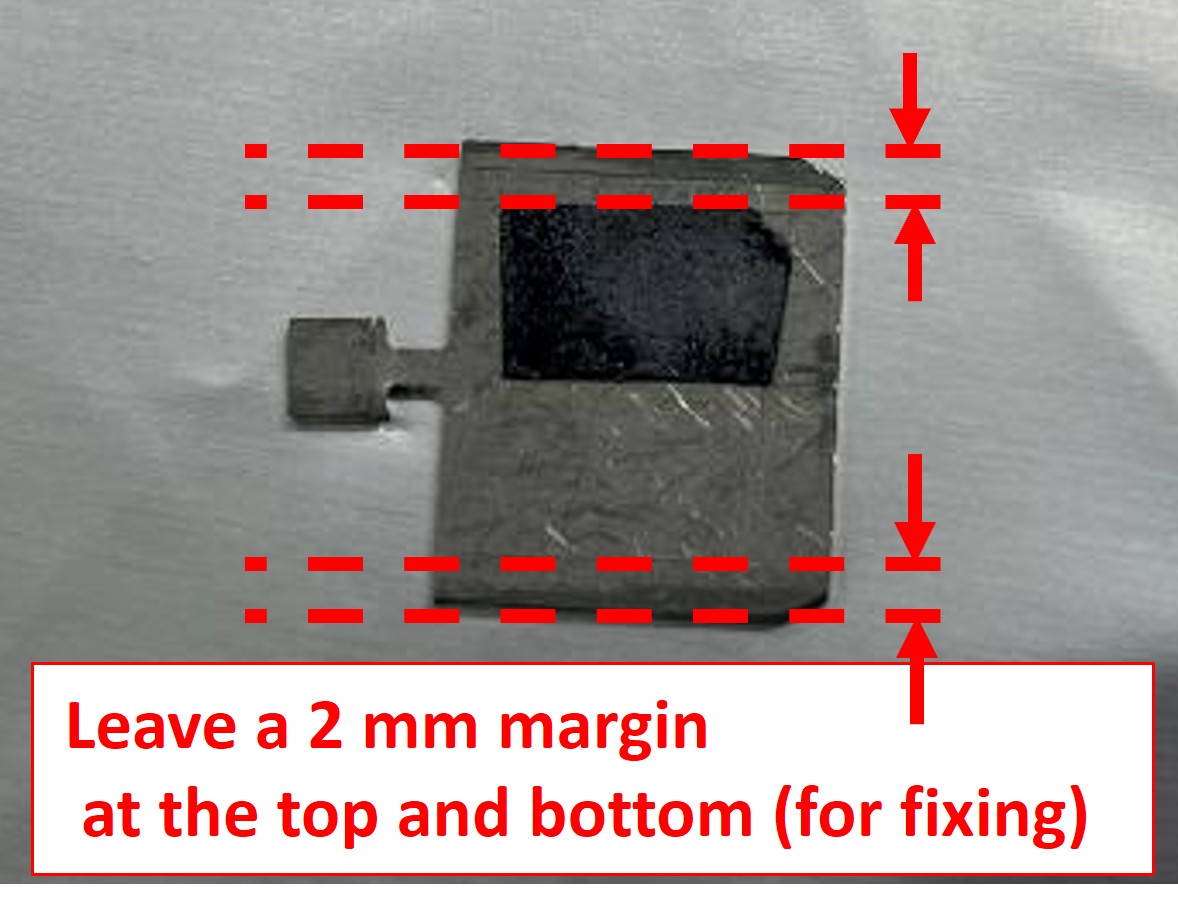

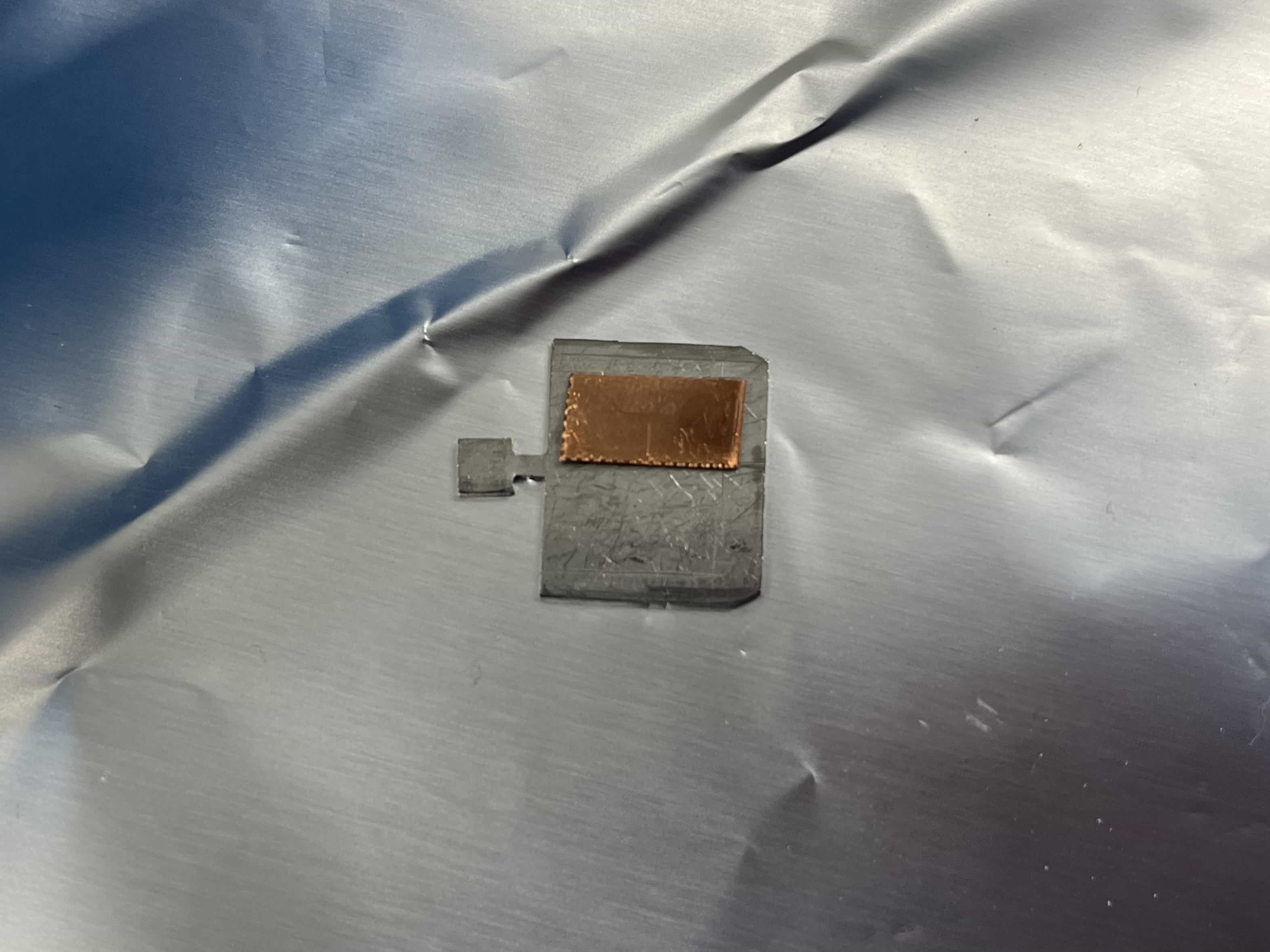

①Cut the carbon tape and attach it to the sample plate.

②Attach the sample.

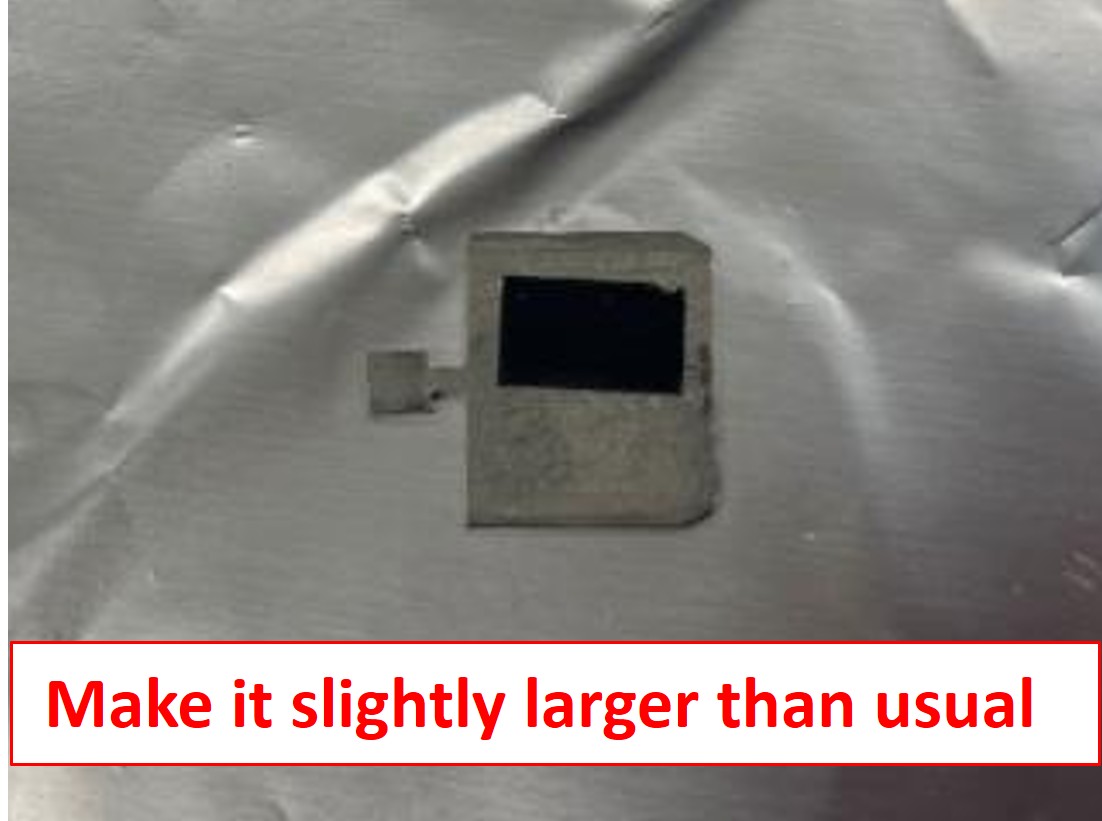

Ex: For Insulating Materials or Thin-Film Substrates with Poor Electrical Conductivity

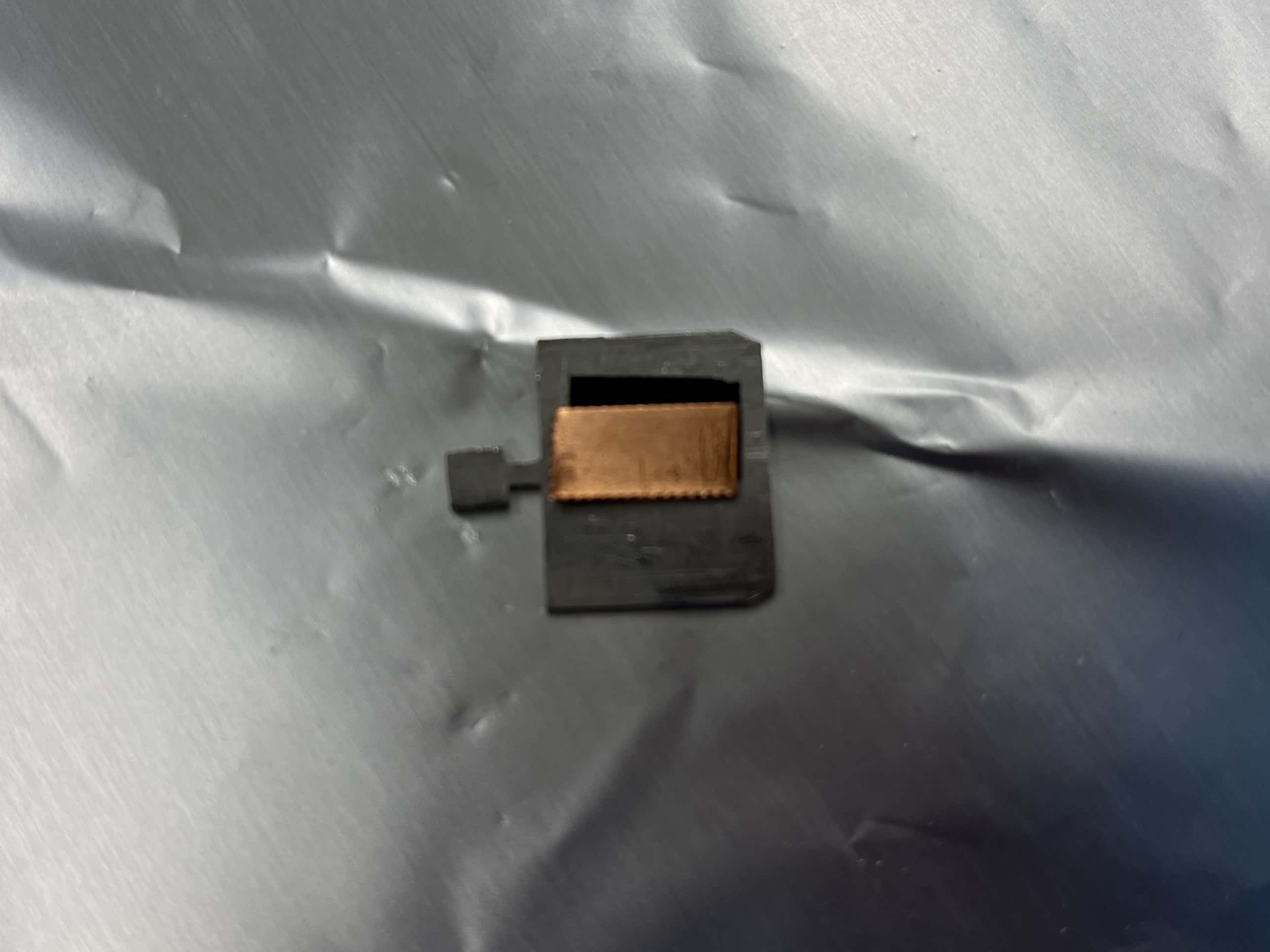

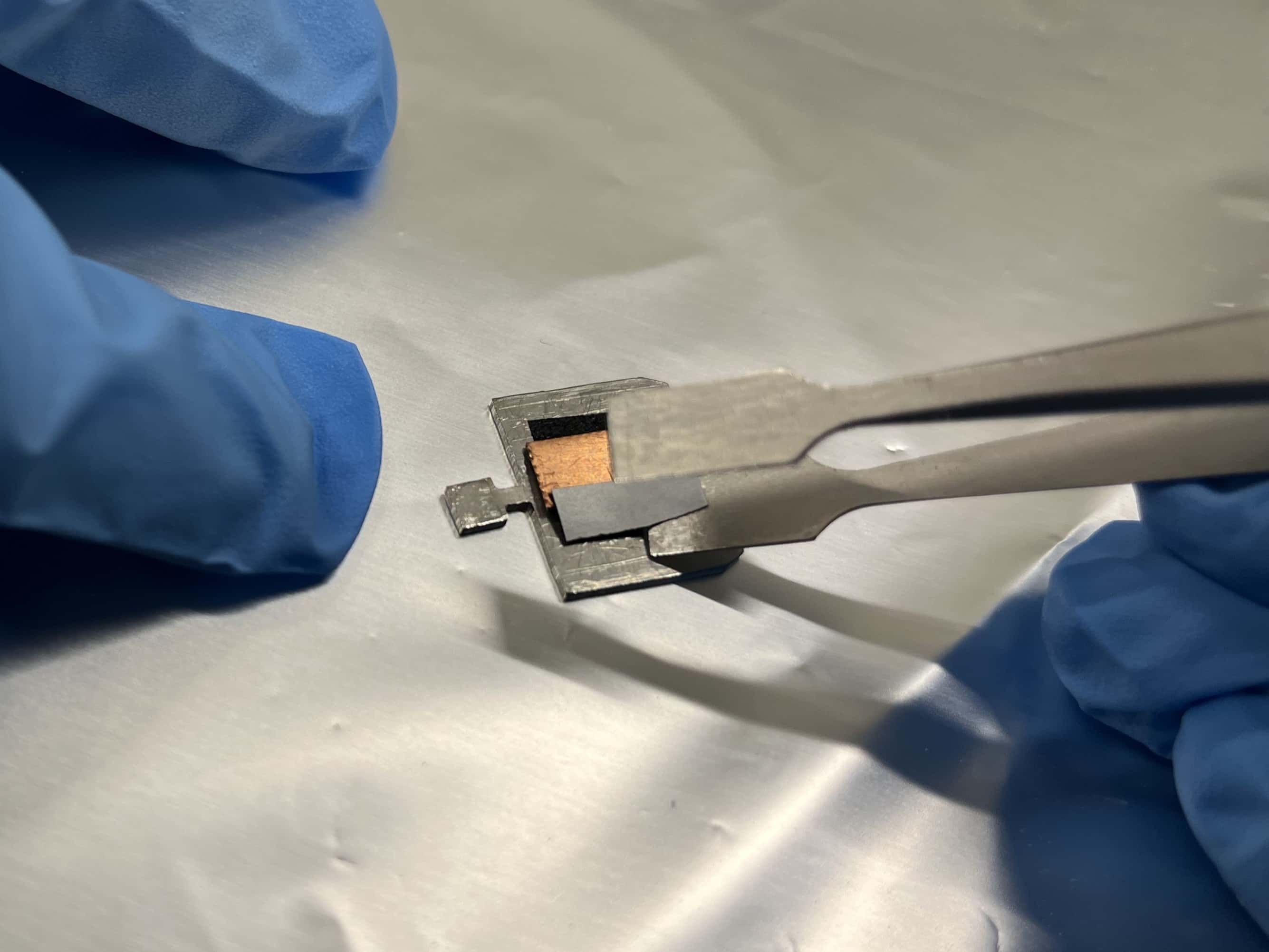

①Cut the carbon tape and attach it to the sample plate.

②Attach the sample.

③Apply carbon tape from the top surface of the sample to the plate to ensure electrical continuity.

④Final setup.

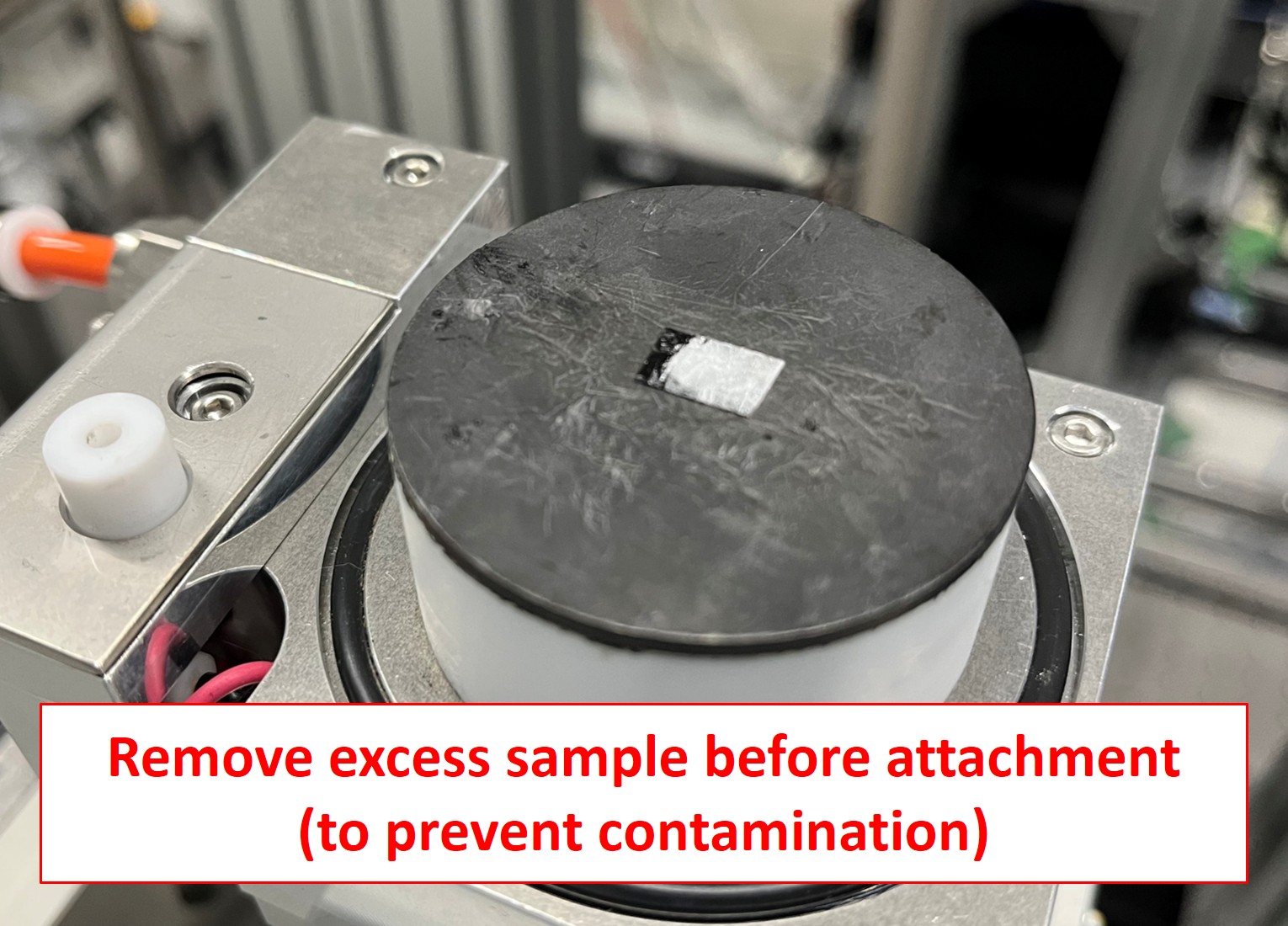

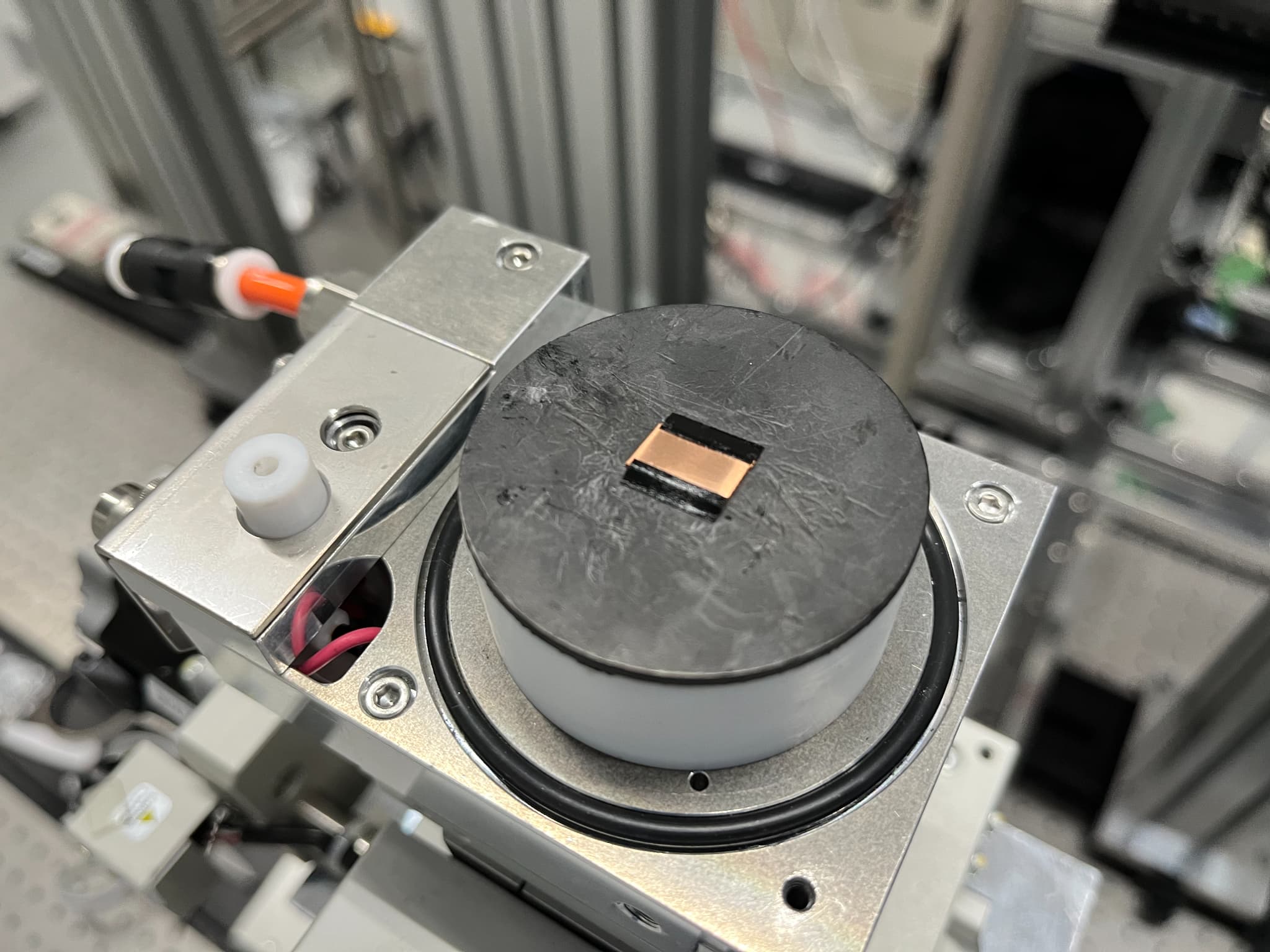

⑤When using an ion chamber for Conversion Electron Yield (CEY) measurements.

Sample Preparation Example Download Link